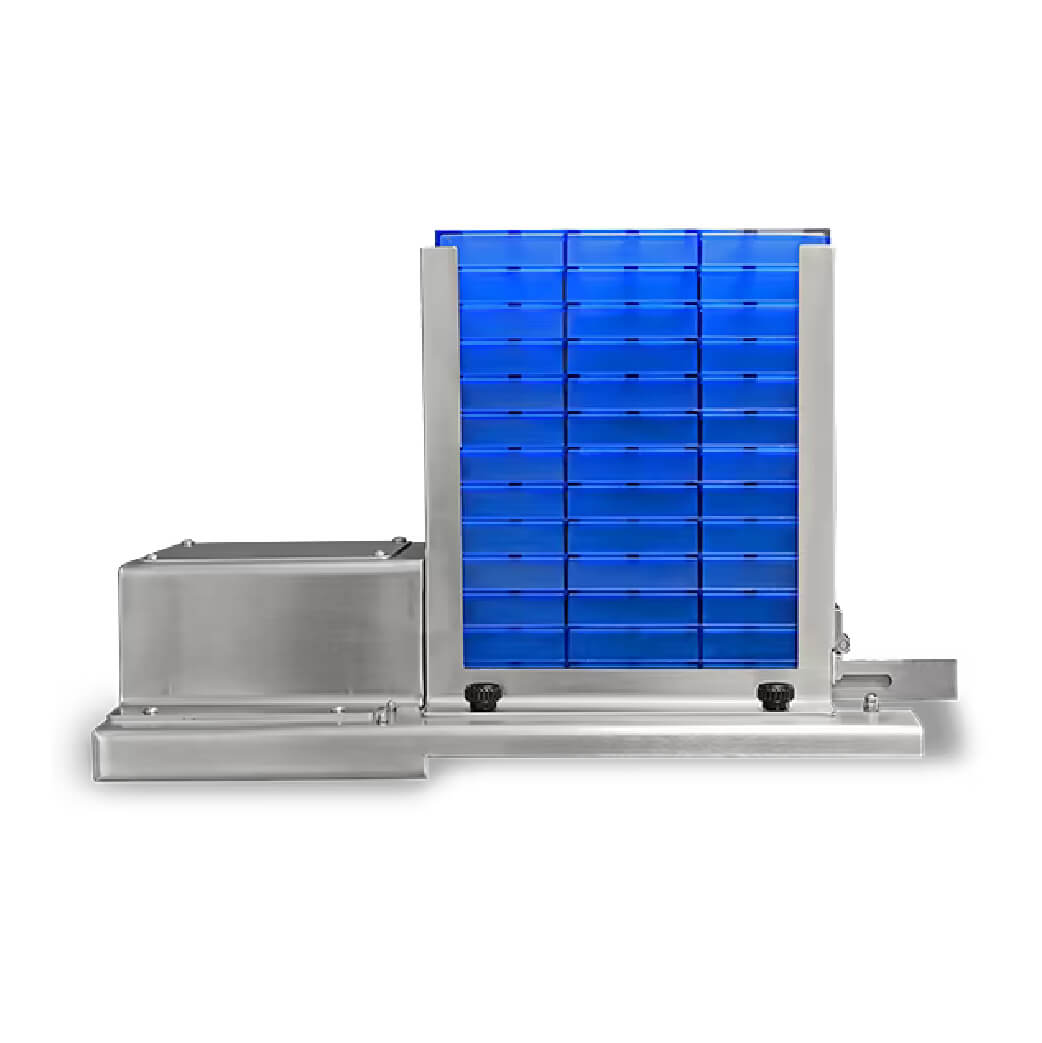

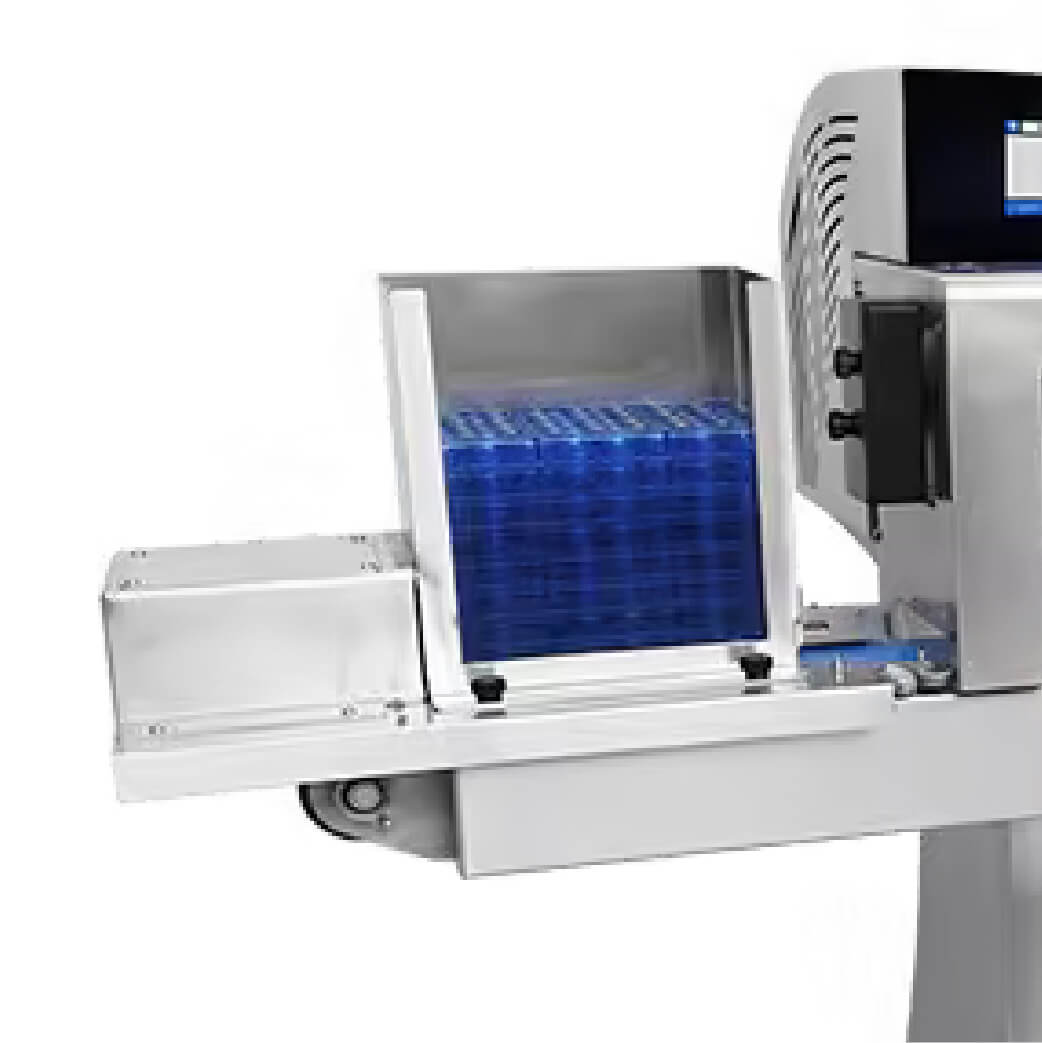

SELMI MOULD LOADER - ONESHOT ACCESSORY

Voltage

400 V/3 Phase/50 Hz

Power

4-5 Kw

Hourly production rate

900-1000 mould

Dimensions

(LxWxH)

2200x1200x1700 mm

DETAILED PRODUCT INFORMATION

1. OVERVIEW

Brand: Selmi – Italy

Application Segment: Automatic chocolate lines with TUTTUNO 4 / 9 / ICE / ICE Plus.

Equipment Introduction:

- MOULD LOADER automatically feeds polycarbonate moulds to the OneShot depositing zone.

- With precise electromechanical assemblies and photoelectric sensors, it ensures continuous, interruption-free cycles, optimizing speed and product consistency.

- Directly connects to VIBRA (vibration), SPIDER (vertical cooling), or TUNNEL 400/600 (horizontal cooling) for a fully automated line.

2. KEY FEATURES

- Continuous automatic feeding: Eliminates manual loading; maintains stable depositing speed.

- Intelligent positioning & sensing: Accurate mould alignment with the TUTTUNO infeed.

- Synchronized electronic control: Auto-stop on full stacks or operator error.

- Multi-model compatibility: TUTTUNO 4, 9, ICE, ICE Plus.

- AISI 304 construction: Hygienic, durable, EU food-safety compliant.

3. INVESTMENT BENEFITS

- +30–40% throughput by removing mould waiting time.

- Lower staffing: One operator can run TUTTUNO + MOULD LOADER + VIBRA.

- Stable line performance: Less misalignment and ingredient loss.

- Ideal for mid-to-large plants targeting full OneShot automation.

4. TECHNICAL SPECIFICATIONS

Specification | Value |

Electrical supply | 220 V / 1 ph / 50 Hz |

Power Required | 0.5 kW – 16 A – 3 poles |

Dimensions (L × W × H) | 1 400 × 900 × 1 250 mm |

Machine weight | ≈ 100 kg |

Feed speed | 450–1,000 moulds/hour (per TUTTUNO model) |

Construction | AISI 304 stainless steel |

Origin | Italy (Italy) |