SELMI FROZEN FRUIT LINE - CHOCOLATE COATING MACHINE FOR FROZEN FRUITS

Voltage

220 V/1 Phase/50 Hz

Belt width

400-600 mm

Cooling Tunnel

400-5 m

600 - 8 m

Dimensions

(LxWxH) mm

9200x1300x1600

12200x1600x1600

DETAILED PRODUCT INFORMATION

1. OVERVIEW

Brand: Selmi – Italy

Application Segment: Dedicated chocolate-coating lines for frozen fruit, artisanal products, premium snacks, and cold-coated candies (chocolate-coated frozen fruits).

Equipment Introduction:

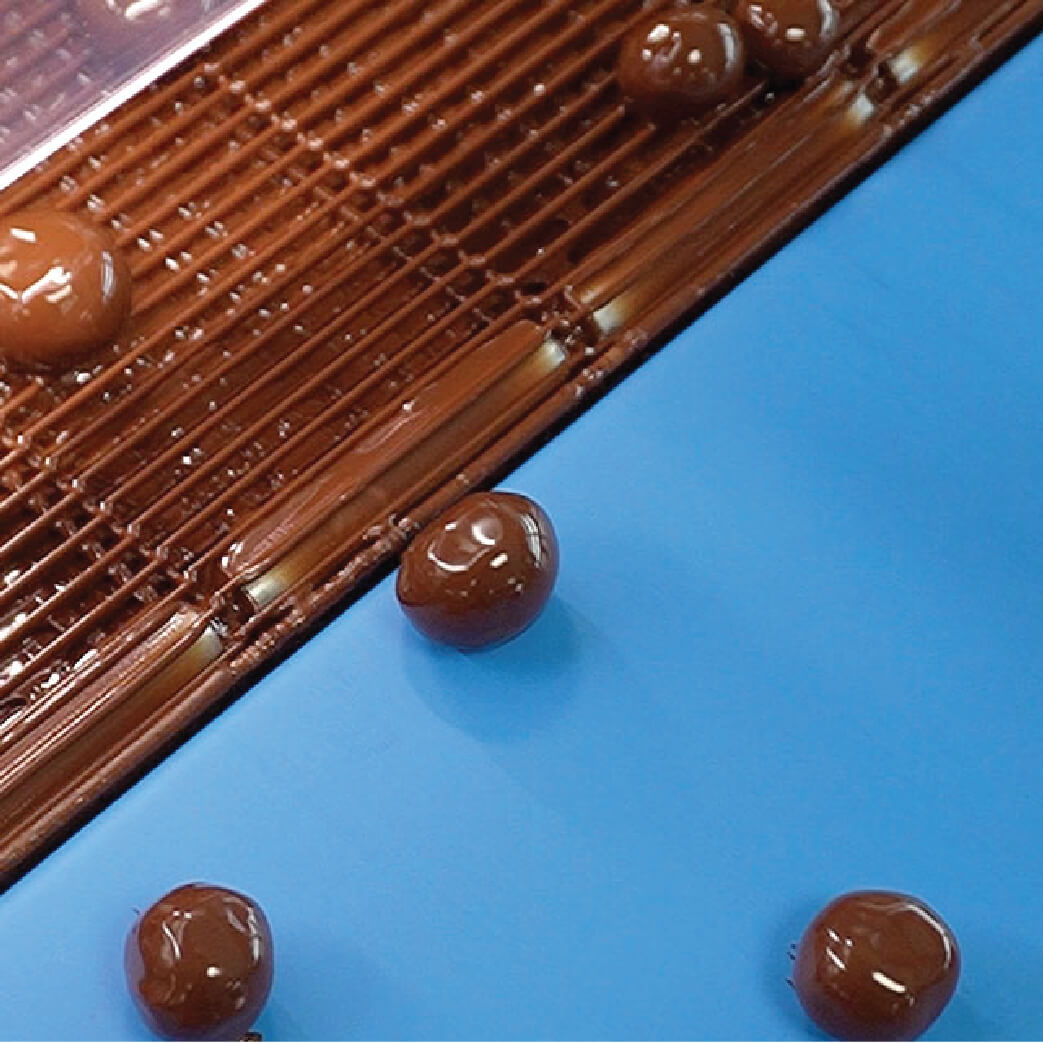

- SThe Selmi Frozen Fruit Line is a complete system engineered to coat frozen fruit with smooth, glossy, and even chocolate.

- A fully integrated configuration—tempering machine + enrobing belt + cooling tunnel—maintains chocolate quality and ensures precise coating under low-temperature conditions.

- Constructed entirely from AISI 304 stainless steel for durability, food safety, and easy sanitation.

- Selmi offers two standard configurations (A & B) suitable for medium and large production, scalable to investment and capacity needs.

2. KEY FEATURES

Specialized technology for frozen fruit

- Mechanical mesh vibration ensures uniform wrap-around coverage without voids or build-ups.

- Single-layer or double-layer coating to suit different fruits and handcrafted items.

Fully integrated line

- Seamless pairing with tempering, enrobing, and cooling tunnel for a closed process: melt → coat → cool.

- Easy connection to Top EX / Cento EX, R400T / R600T, Tunnel 400 / Tunnel 600 based on scale.

Electronic control – high efficiency

- Automatic control of belt speed, blower, and heaters via touchscreen.

- Stable output, chocolate savings, and optimized operation.

Industrial design – easy sanitation

- Full AISI 304 surfaces; plexiglass safety guards for protection while maintaining visibility.

- Quick-release parts for fast cleaning in continuous production.

3. STANDARD CONFIGURATIONS

Components:

- 2 × Top EX Tempering Machines

- 1 × R400T PLUS Enrobing Belt

- 1 × Cooling Tunnel 400 (5 m)

Overall Dimensions: 9,200 × 1,300 × 1,600 mm

Notes:

- 400 mm belt for medium throughput.

- Compact, easy to install in restricted spaces.

- Ideal for trials, R&D, and medium-scale handcrafted production.

Components:

- 2 × Cento EX Tempering Machines

- 2 × R600T Enrobing Belts

- 1 × Cooling Tunnel 600 (8 m)

Overall Dimensions: 12,200 × 1,600 × 1,600 mm

Notes:

- 600 mm belt for industrial-scale capacity.

- Longer 8 m tunnel for enhanced cooling efficiency.

- Continuous operation for high-volume manufacturing.

4. INVESTMENT BENEFITS

- Premium finish: Even, smooth, glossy coatings meeting EU export standards.

- Higher efficiency & lower losses: Electronic control reduces chocolate waste and stabilizes quality.

- Broad applications: Coating for fruit, nuts, energy bars, cold candies, and premium handcrafted goods.

- Scalable investment: Choose Configuration A (medium) or B (large) per budget and capacity.

- Easy synchronization: Integrates seamlessly across the Selmi line from tempering to cooling tunnels..

5. TECHNICAL SPECIFICATIONS

Specification | Configuration A | Configuration B |

Tempering Machines | 2 × Top EX | 2 × Cento EX |

Enrobing Belt | R400T PLUS | R600T |

Cooling Tunnel | 400 – 5 m | 600 – 8 m |

Belt Width | 400 mm | 600 mm |

Dimensions L×W×H | 9,200 × 1,300 × 1,600 mm | 12,200 × 1,600 × 1,600 mm |

Power Supply | 220 V / single-phase / 50 Hz) | 220 V / single-phase / 50 Hz |

Compressed Air Connection | Required (clean & dry) | Required (clean & dry) |

Construction | AISI 304 stainless steel | AISI 304 stainless steel |

Origin | Italy | Italy |