An ideal chocolate bar always has a smooth, glossy surface, produces a clear “snap” when broken, and melts evenly in the mouth. In reality, however, many chocolate makers struggle with the same issue: why chocolate turns dull, develops white spots, or melts too quickly—despite using the same formula.

Most of these problems do not come from the ingredients, but from improper chocolate tempering techniques. Tempering is the critical step that determines the crystal structure of cocoa butter, directly affecting color, shine, texture, and product stability. Understanding why chocolate turns dull is the first step toward fixing the problem at its root. Below are three fundamental tips that explain why chocolate turns dull and how to prevent it in real production.

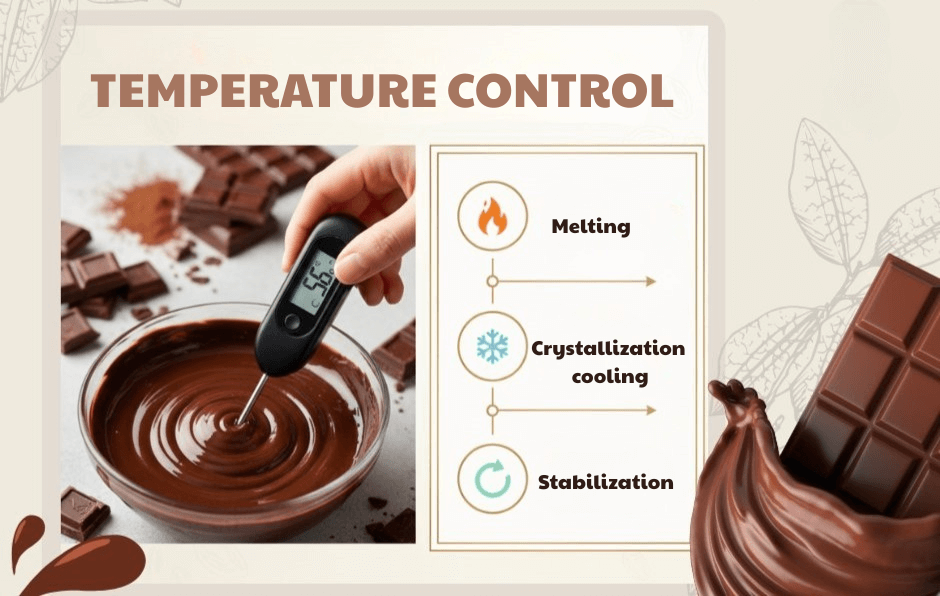

Temperature – the golden key behind why chocolate turns dull or glossy

A glossy chocolate bar does not happen by chance. One of the most common reasons why chocolate turns dull is improper temperature control during tempering. When temperatures fall out of range, chocolate is prone to bloom, dull surfaces, softness, and rapid melting when handled.

In chocolate tempering, temperature is the “heart” of the entire process. Each type of chocolate has three critical temperature stages required for proper cocoa butter crystallization. For dark chocolate, this typically involves melting at 55–58°C, cooling down to 28–29°C, then reheating to around 31–32°C before molding. Milk and white chocolate require lower temperature ranges and more precise control due to their higher sensitivity to heat.

A common mistake that explains why chocolate turns dull is measuring temperature too close to the pot or machine walls, where readings do not accurately reflect the core chocolate mass. When tempering large batches, maintaining stable temperatures by feel alone is nearly impossible. This is where specialized tempering equipment becomes essential, helping maintain precise and consistent temperatures and significantly reducing the risk of dull chocolate from the very first step.

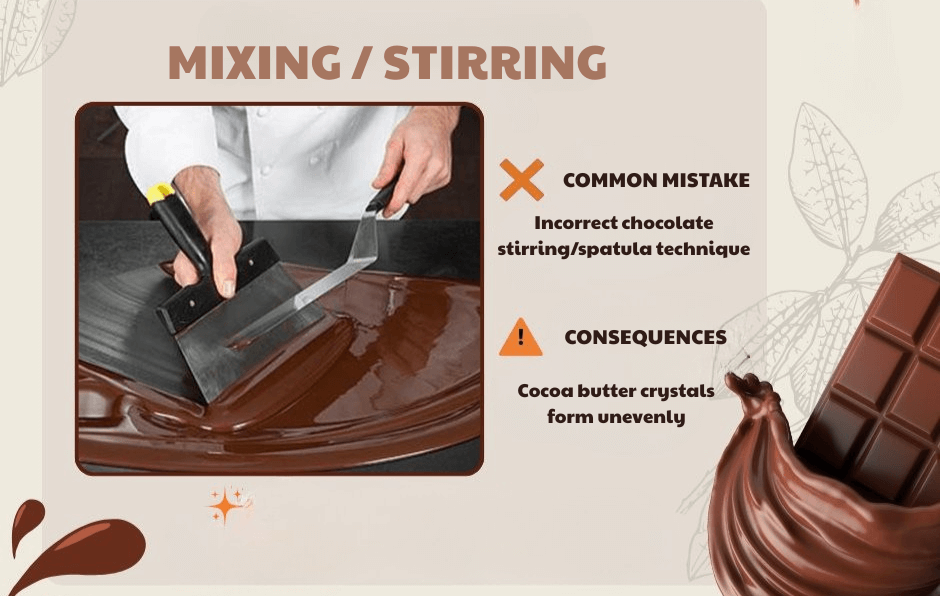

Mixing – the silent factor behind why chocolate turns dull

Even with correct temperature control, chocolate can still turn dull if mixing techniques during the cooling phase are incorrect—another overlooked reason why chocolate turns dull, especially among beginners.

During tempering, mixing is not simply about stirring evenly; it directly guides cocoa butter crystal formation. Uneven force, inconsistent stirring direction, or overly aggressive scraping can result in unstable crystal structures. The outcome is chocolate that clumps, breaks irregularly, or loses surface gloss after setting.

When tempering manually, chocolate must be spread and stirred gently, consistently, and in one direction to encourage uniform crystal development. For larger batches, maintaining this rhythm by hand is extremely difficult. This is why many chocolate workshops and brands invest in tempering machines, where stirring speed and temperature are synchronized—helping reduce inconsistencies and prevent dull finishes.

Water and humidity – hidden reasons why chocolate turns dull

Even a tiny amount of water can ruin an entire batch of chocolate. When water or moisture comes into contact with warm chocolate, seizing occurs, causing the chocolate to clump, thicken, and completely lose its smooth texture. This is a critical but often underestimated reason why chocolate turns dull, loses shine, and becomes difficult to mold.

Moisture often comes from inadequately dried utensils, humidity in the air, or washing tempering machines with water between chocolate types. Although invisible, residual moisture is enough to disrupt cocoa butter crystal formation and destabilize chocolate structure.

To prevent dullness caused by moisture, all tools must be completely dry before use. When switching chocolate types in a tempering machine, never clean with water. Instead, use the new chocolate itself to flush out remaining chocolate, ensuring a dry and stable environment for the next batch.

Dull chocolate, white spots, or loss of shine are not random defects—they are clear indicators that the tempering process needs adjustment. From temperature control and mixing techniques to moisture management, every small detail contributes to why chocolate turns dull or glossy.

These three basic tips form the foundation for mastering chocolate tempering, minimizing common defects, and producing stable, glossy chocolate bars. In the next part of the Chocolate Tempering Tips series, we will explore molding timing, storage conditions, and advanced issues commonly encountered in real-world chocolate production.