ICETEAM 1927 COMPACTA 4 SILVER – GELATO MACHINE WITH PASTEURIZATION

Electrical supply

230 V/1 pha/50 Hz

Power

4.5 Kw

Hourly production

20-36 L/h

Quantity per cycle

1.5-4 Kg

Weight

220 Kg

Dimensions (W × D × H)

59x73x93 cm

PRODUCT DETAILS

1. OVERVIEW

Brand: Iceteam 1927 – Italy (Ali Group)

Application Segment: Professional 2-in-1 equipment for gelato shops, restaurants, hotels, training centers, or culinary R&D labs.

Equipment Introduction:

COMPACTA 4 is a professional 2-in-1 machine designed by Iceteam 1927 – Italy, integrating both pasteurization and batch freezing in a single unit.

It is the perfect solution for small gelato shops, training centers, classrooms, or R&D labs, where a compact machine can perform the full gelato production process with industrial-standard quality.

This equipment allows users to process the entire workflow—from fresh ingredients to finished gelato—in a single cycle, saving time, reducing waste, and ensuring food safety.

2. KEY FEATURES

Professional Gelato Production in One Step

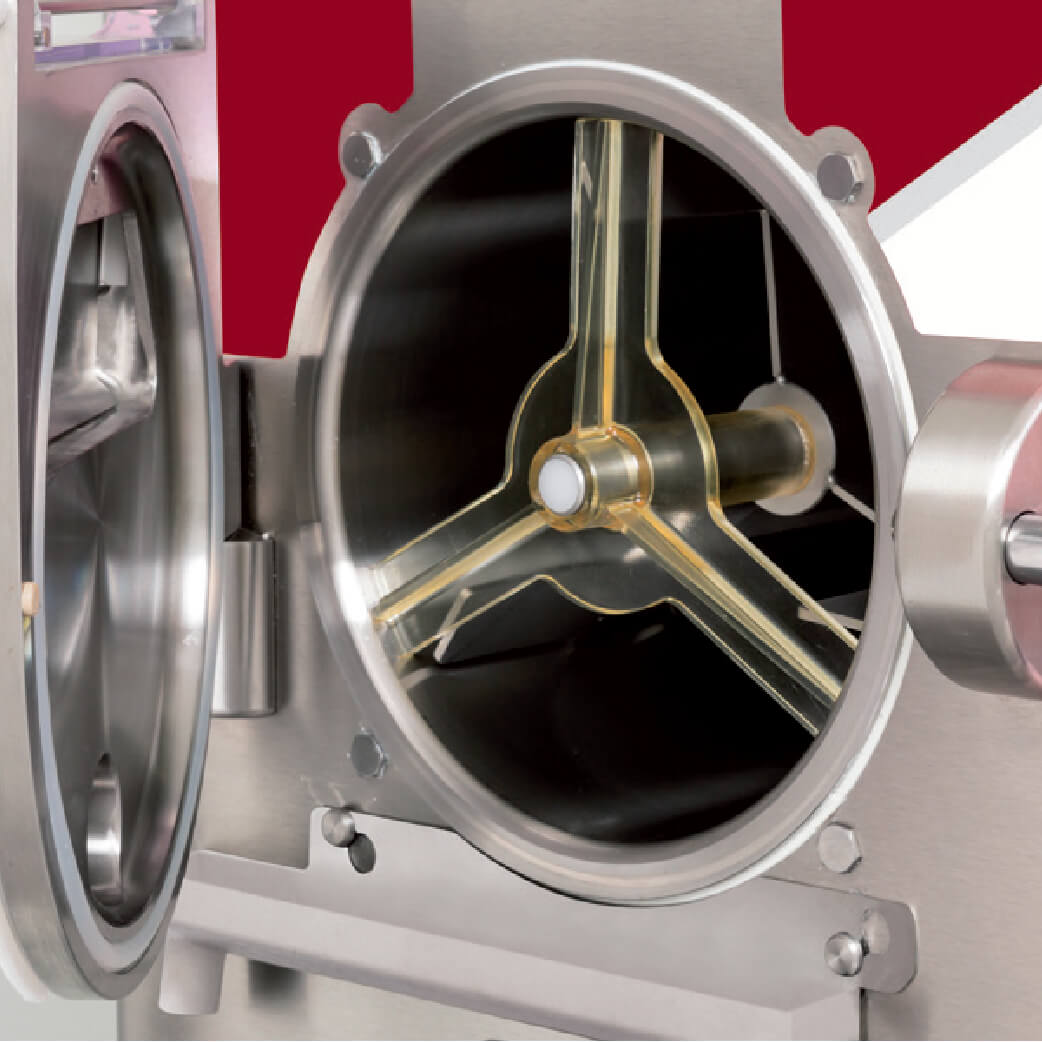

Two independent chambers: heating tank on top, freezing chamber below.

Enables full gelato production from raw ingredients to finished product without transferring batches.

Minimizes contamination risks and ingredient loss.

Small Batch Capacity – Suitable for Various Models

Batch size: 1.5–4 kg (≈4 L).

Hourly production: 20–36 L/h, ideal for test production, demos, or direct service.

Precise Heating & Pasteurization

Heating up to 85 °C, with selectable low/high pasteurization or recipe-specific cooking.

Automatic temperature control ensures consistent and uniform results across batches.

Fast Freezing – Smooth Italian Texture

High-performance cooling combined with continuous mixing.

Produces smooth, airy gelato while preserving moisture and natural flavor.

Compact Design – Easy to Operate & Clean

Dimensions: 59 × 73 × 93 cm – suitable for table-top or open counter placement.

Entire body made of AISI 304 stainless steel, durable and easy to clean.

Intelligent electronic touch control panel allows programming and real-time monitoring of temperature and cycles.

3. INVESTMENT BENEFITS

Space-saving: One machine replaces two separate units (pasteurizer + freezer).

Ensures food safety: Closed workflow reduces contamination risks.

Increases production efficiency: Reduces batch handling time and costs.

Ideal for training and research: Easy to control technical parameters for new recipe experiments.

Simple operation and low maintenance: Suitable for beginners and professional chefs alike.

4. TECHNICAL SPECIFICATIONS

Specification | Value |

Quantity per Cycle | 1.5–4 kg |

Hourly Production | 20–36 L/h |

Energy Consumption | 4.5 kW |

Electrical Supply | 230 V / 1 Phase / 50 Hz |

Dimensions (W × D × H) | 59 × 73 × 93 cm |

Cooling System | Air Cooling |

Weight | 220 kg |

ICETEAM 1927 COMPACTA VARIO 8 SILVER – GELATO MACHINE WITH PASTEURIZATION

Electrical supply

400 V/3 ph/50 Hz

Power

9 Kw

Hourly production

14-68 L/h

Quantity per cycle

1.5-8 Kg

Weight

290 Kg

Dimensions (W × D × H)

60x77x153 cm

PRODUCT DETAILS

1. OVERVIEW

Brand: Iceteam 1927 – Italy (Ali Group)

Application Segment: Professional 2-in-1 equipment for gelato labs, high-end production facilities, R&D, and 5-star restaurants/hotels.

Equipment Introduction:

COMPACTA VARIO 8 SILVER is a professional pasteurization & batch freezing machine developed by Iceteam 1927 – Italy, featuring VARIO technology for adjustable mixing speed during freezing.

This allows precise control over smoothness, density, and texture of gelato according to each recipe and product style.

Designed for professional gelato shops, high-end restaurants/hotels, or R&D labs, the machine delivers stable performance, high precision, and customizable gelato texture in a compact operational footprint.

2. KEY FEATURES

VARIO Technology – Customizable Gelato Texture

Adjustable mixing speed during freezing for precise control over smoothness and density.

Flexibility to produce various product types – from soft gelato to denser forms for take-away or desserts.

Two Separate Chambers – Closed Production Process

Upper chamber: Pasteurizes ingredients up to 85 °C – ensures hygiene and stable structure.

Lower chamber: Fast freezing with continuous mixing – maintains uniform, perfectly smooth gelato texture.

High Capacity – Stable Performance

Batch size: 1.5–8 kg (≈8 L).

Hourly production: 14–68 L/h, suitable for medium-to-high intensity continuous production.

User-Friendly Digital Control

Soft digital panel displays real-time time, temperature, and mixing speed.

Easy programming of heating – freezing – holding cycles, with batch completion alerts..

AISI 304 Stainless Steel Structure – Durable & Hygienic

Entire body made of AISI 304 stainless steel, corrosion-resistant and easy to clean.

Robust design, quiet operation, ideal for open kitchens or artisanal production areas.

3. INVESTMENT BENEFITS

Two functions in one machine: saves space and investment costs.

Customizable product texture: adjust mixing speed for each recipe and gelato type.

Ensures hygiene & food safety: closed process between pasteurization and freezing chambers.

Suitable for all-day production: stable cooling performance and long service life.

Ideal for R&D: easy monitoring and control of process parameters for new recipes.

4. TECHNICAL SPECIFICATIONS

Specification | Value |

Quantity per Cycle | 1.5–8 kg |

Hourly Production | 14–68 L/h |

Energy Consumption | 9 kW |

Electrical Supply | 400 V / 3 Phase / 50 Hz |

Dimensions (W × D × H) | 60 × 77 × 153 cm |

Cooling System | Water Cooling |

Weight | 290 kg |

ICETEAM 1927 COMPACTA VARIO 8 ELITE – GELATO MACHINE WITH PASTEURIZATION

Electrical supply

400 V/3 ph/50 Hz

Power

9 Kw

Hourly production

14-68 L/h

Quantity per cycle

1.5-8 Kg

Weight

290 Kg

Dimensions (W × D × H)

60x77x153 cm

PRODUCT DETAILS

Brand: Iceteam 1927 – Italy

Application Segment: Premium 2-in-1 gelato equipment for gelato shops, 5-star restaurants/hotels, R&D labs, or dessert training centers.

Equipment Introduction:

COMPACTA VARIO 8 ELITE is the top-tier version of the pasteurization & batch freezing line from Iceteam 1927 (Italy), part of the Ali Group – a global leader in F&B equipment.

It is designed for professional gelato shops, high-end restaurants, or R&D facilities requiring a comprehensive, flexible, and durable solution to perfectly control product quality.

With two independent chambers (heating tank and freezing chamber) and VARIO technology for precise mixing speed control, Compacta Vario 8 Elite allows users to adjust gelato smoothness, density, and texture according to each recipe.

2. KEY FEATURES

VARIO Technology – Full Texture Control

Adjustable mixing speed during freezing for precise control of smoothness and density.

Easily produce various textures: soft gelato, firm ice cream, smooth sorbet, or dense semifreddo.

2-in-1 Process – Pasteurization & Freezing in One Closed Cycle

Upper tank: Heats and pasteurizes ingredients up to 85 °C – ensures hygiene and stable mix structure.

Lower tank: Fast freezing with continuous mixing – produces smooth gelato while preserving moisture and natural flavor.

Reduces production time – no batch transfer required, minimizing contamination risk.

High Performance – Continuous All-Day Operation

Batch size: 1.5–8 kg (≈8 L) for high-intensity operation.

Hourly production: 14–68 L/h, ideal for professional gelato shops or semi-wholesale production.

Digital Control – Precise & Easy to Use

Soft digital panel shows real-time temperature, time, and mixing speed.

Automated heating & freezing cycles reduce operator error and optimize workflow..

Premium Design – European Standards

Body made from AISI 304 stainless steel, corrosion-resistant, EU food safety compliant.

Compact size (60 × 77 × 153 cm) – suitable for open kitchens or modern gelato labs.

3. INVESTMENT BENEFITS

Space & cost efficient: One machine replaces both pasteurizer and batch freezer.

Versatile product textures: Flexibly adjust smoothness, aeration, or density per recipe.

Ensures maximum hygiene: Closed process from fresh ingredients to finished product.

Reduces production time: Automated cycles save labor and energy.

Enhances creative productivity: Ideal for testing new recipes, training, or daily production.

.

4. TECHNICAL SPECIFICATIONS

Specification | Value |

Quantity per Cycle | 1.5–8 kg |

Hourly Production | 14–68 L/h |

Energy Consumption | 9 kW |

Electrical Supply | 400 V / 3 Phase / 50 Hz |

Dimensions (W × D × H) | 60 × 77 × 153 cm |

Cooling System | Water Cooling |

Weight | 290 kg |

MÁY LÀM GELATO KẾT HỢP THANH TRÙNG ICETEAM 1927 COMPACTA 12 Elite

Điện áp

400 V/3 pha/50 Hz

Điện năng tiêu thụ

15 Kw

Sản lượng

14-120 L/h

Sản lượng theo mẻ

1.5-12 Kg

Kích thước

(WxDxH)

60x77x153 cm

THÔNG TIN CHI TIẾT VỀ SẢN PHẨM

1. TỔNG QUAN

Thương hiệu: Iceteam 1927 – Italy (Ali Group)

Phân khúc ứng dụng: Thiết bị gelato 2-trong-1 cao cấp dành cho tiệm gelato, nhà hàng, khách sạn 5 sao, phòng R&D hoặc trung tâm đào tạo nghề dessert.

Giới thiệu thiết bị:

- Compacta Vario 12 Elite là mẫu máy gelato chuyên nghiệp tích hợp thanh trùng và cấp đông trong cùng một thiết bị, giúp người dùng hoàn thiện toàn bộ quy trình sản xuất gelato theo chuẩn châu Âu.

- Thiết kế hai buồng độc lập – bồn gia nhiệt phía trên và buồng cấp đông ngang phía dưới – cho phép vận hành liên tục, đảm bảo năng suất cao và kiểm soát nhiệt độ chính xác.

- Công nghệ VARIO (Double Inverter) tự động điều chỉnh tốc độ khuấy và công suất làm lạnh theo loại và lượng hỗn hợp, giúp giảm tới 30% điện năng và nước tiêu thụ.

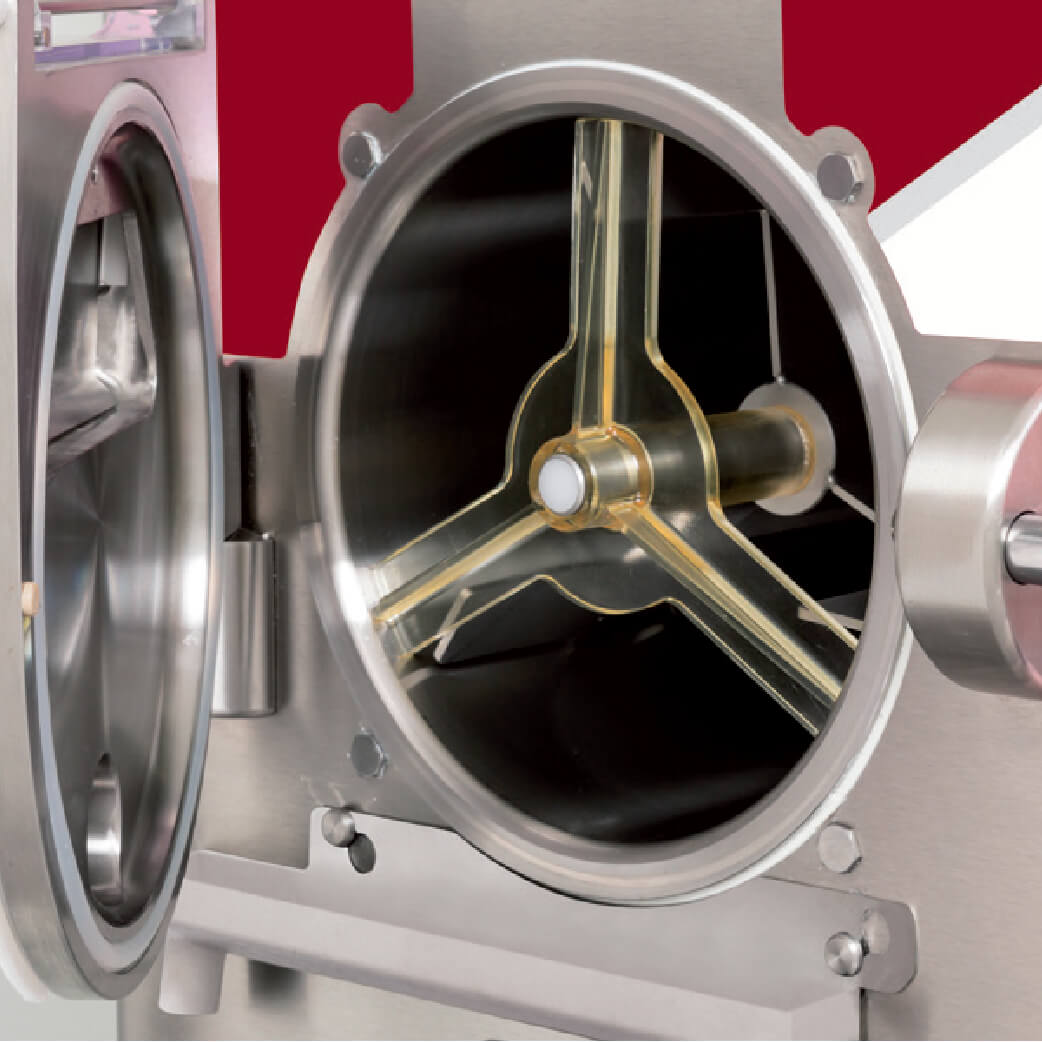

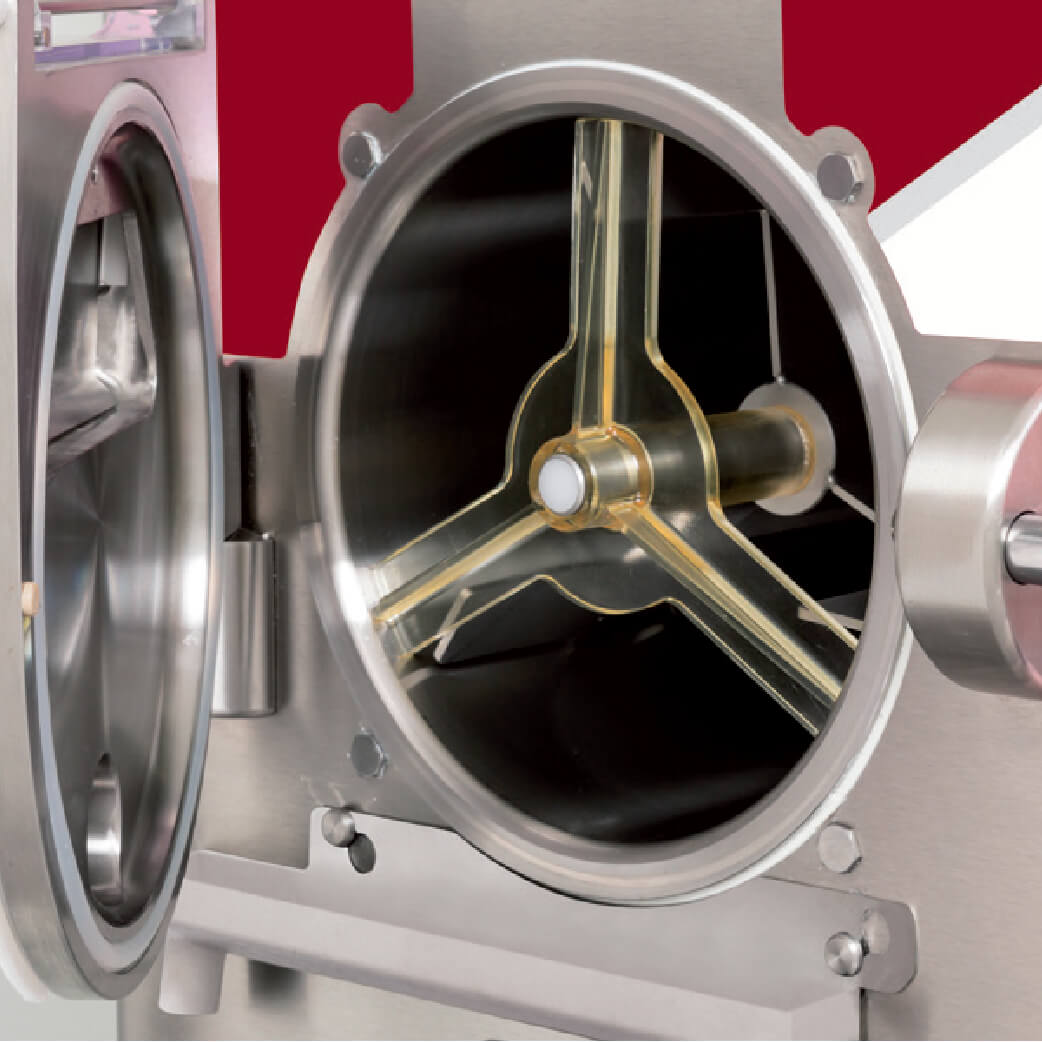

- Phiên bản Elite được trang bị Chef Boiler Door có piston xoay tiện dụng, cùng Pro Door cách nhiệt độc quyền của Iceteam 1927, giúp tăng hiệu quả cấp đông và nâng cao chất lượng gelato.

2. ƯU ĐIỂM NỔI BẬT

Công nghệ VARIO – Điều chỉnh linh hoạt

- Hệ thống Double Inverter thay đổi tốc độ và công suất làm lạnh tự động.

- Phù hợp cho cả mẻ nhỏ và mẻ lớn, tối ưu năng lượng và hiệu suất.

- Giảm đến 30% tiêu thụ điện và nước so với thế hệ trước.

Chu trình 2-trong-1 – Thanh trùng & cấp đông khép kín

- Bồn trên: thanh trùng hỗn hợp ở 85°C, đảm bảo vệ sinh tuyệt đối.

- Bồn dưới: cấp đông nhanh, đảo liên tục để tạo kết cấu mịn mượt.

- Giúp rút ngắn quy trình sản xuất, hạn chế nhiễm khuẩn chéo.

Thiết kế cao cấp & thông minh

- Cửa buồng cấp đông Pro Door cách nhiệt, nâng cao hiệu suất làm lạnh.

- Chef Boiler Door với piston xoay giúp rót hỗn hợp tiện lợi.

- Thân máy inox AISI 304 đạt chuẩn an toàn thực phẩm châu Âu.

- Hỗ trợ ứng dụng M2M Dialog – cho phép giám sát và hỗ trợ kỹ thuật từ xa.

3. LỢI ÍCH ĐẦU TƯ

- Tối ưu chi phí: Một thiết bị thay thế cả máy thanh trùng và máy cấp đông.

- Tiết kiệm năng lượng: Giảm đến 30% điện và nước tiêu thụ.

- Đảm bảo vệ sinh tuyệt đối: Chu trình khép kín, hạn chế nhiễm khuẩn.

- Tăng năng suất sáng tạo: Phù hợp thử nghiệm công thức mới, R&D và vận hành liên tục.

- Chất lượng gelato đồng nhất: Kiểm soát chính xác kết cấu và độ mịn của sản phẩm.

4. THÔNG SỐ KỸ THUẬT

Thông số | Giá trị |

Số lượng trên mỗi chu trình (Quantity per cycle) | 1.5 – 12 kg |

Công suất/giờ (Hourly production) | 14 – 120 liters |

Công suất lắp đặt (Installed power) | 15 kW |

Nguồn điện (Electrical supply) | 400 V / 3 phase / 50 Hz |

Kích thước (R × S × C) (Dimensions – W × D × H) | 60 × 77 × 153 cm |