Chocolate Equipment

Vietnam is known as one of the few countries with high-quality cacao beans and home to some of the “best chocolates in the world” – The New York Times. Recently, the trend of investing in cacao farming and premium chocolate production in Vietnam has been growing strongly, opening up many new opportunities.

As the official representative of Selmi in Indochina, TIM CORP is committed to bringing the finest machines and the most effective technical solutions to help chocolate makers in Vietnam create proudly Made-in-Vietnam chocolate products.

WHAT BEAN TO BAR IS

“Every piece of premium chocolate begins with quality cacao beans – and a meticulously controlled production process.”

Amid the global rise of the artisanal chocolate movement, Bean to Bar is more than just a production method – it is a declaration by true chocolate artisans. It represents the choice of those who prioritize quality, transparency, and sustainability in every product.

At TIM Corp, we are proud to support this journey by offering a comprehensive range of equipment solutions from Selmi (Italy) – a world-leading brand in Bean to Bar chocolate production.

Why has Bean to Bar become the new standard in modern chocolate making?

Premium Quality

Complete control over the entire process – from cacao bean to final product.

Authentic Flavor

Preserves the unique characteristics of each growing region.

Transparency & Sustainability

Ensures ingredient traceability and a safe, ethical production process.

As the official distributor of Selmi in Vietnam, TIM Corp provides end-to-end equipment solutions, enabling chocolate makers to bring the Bean to Bar model to life – from handcrafted to semi-industrial scale.

Roasting

The Selmi roaster allows precise control of temperature and time – helping to fully release the original aroma while laying the foundation for the next processing steps.

Winnowing

After roasting, the cacao beans are de-shelled using a specialized winnower system. Selmi’s equipment ensures the complete removal of the thin outer husk, yielding clean, pure nibs ready for the grinding stage.

Grinding

Before creating a smooth chocolate mixture, the cacao beans must be coarsely ground into a thick paste known as cacao liquor – a crucial step in the bean-to-bar process that releases the natural cocoa butter and prepares the material for the next stage of refinement.

Refining

After coarse grinding, the cacao liquor needs to be finely refined to achieve the ideal smoothness, giving the chocolate a silky texture with a particle size of 20–25 microns.

Filtering

The Vaglio machine filters the chocolate mixture after refining, ensuring a smooth, impurity-free final product – ideal for professional chocolate makers.

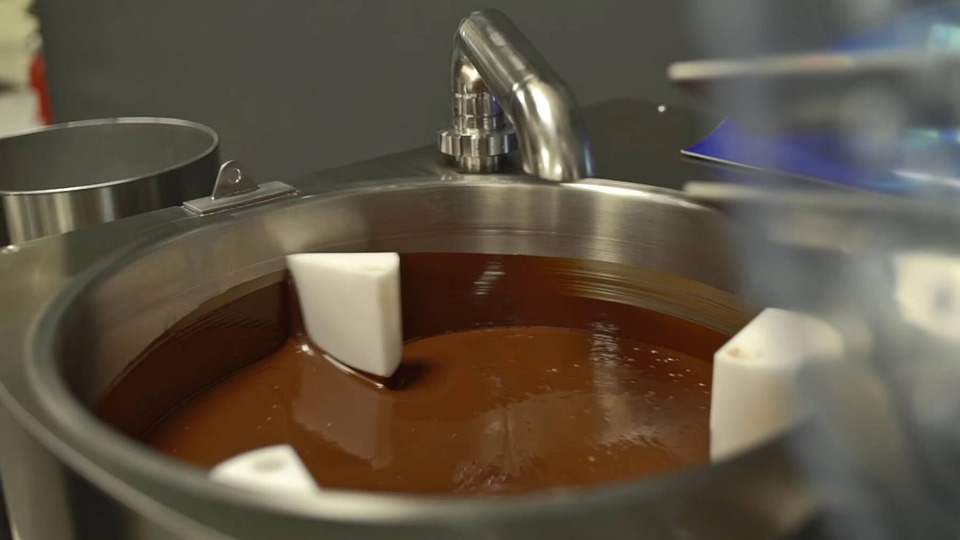

Conching

Conching is a crucial step in fine-tuning flavor through continuous mixing, which helps evaporate acids and remove any remaining moisture in the chocolate—thereby optimizing both taste and overall product quality. Selmi’s conching equipment ensures a smooth, efficient, and continuous process, resulting in chocolate that is refined in both flavor and texture.

Tempering

The tempering stage creates the ideal crystal structure in chocolate – ensuring a glossy finish after molding, a satisfying “snap” sound, and optimal shelf stability.