COMFIT – Professional Chocolate Coating Machine with Integrated Automatic Spray System

COMFIT is a high-end chocolate coating machine specially designed for chocolate workshops, candy manufacturers, and coated nut production. Built entirely with AISI 304 stainless steel, COMFIT meets strict hygiene standards, offers high durability, and is easy to maintain—making it the ideal choice for products such as chocolate dragees, sugar-coated candies, and more.

Key Features of the COMFIT Chocolate Coating Machine

Integrated smart cooling system that controls airflow into the rotating drum, optimizing the drying process to ensure an even and well-adhered chocolate coating.

Polishing technology using thermal resistors delivers a smooth, glossy finish that enhances the visual appeal and texture of each coated piece.

Flexible electronic control panel allows easy temperature adjustment to suit different product types.

Quick switching between hot and cold air, making it adaptable for multiple stages of the professional chocolate coating process.

Removable air filters ensure food safety and simplify maintenance.

COMFIT + Spray System – The Ideal Duo for Modern Chocolate Coating Lines

When paired with the automatic Spray System, the COMFIT chocolate coating machine enables businesses to:

Achieve uniform coating and visually appealing surfaces

Reduce cleaning time and increase production efficiency

Elevate product quality, making it ideal for companies looking to enhance their finished goods

COMFIT with Spray System – a professional solution for precision, performance, and premium presentation.

Electrical specification

220 V, 1 pha, 50 Hz

Power required

1,8 Kw – 16 A – 3 plots

Dimensions

(L x W x H)

720 x 1100 x 1500 mm

Tank capacity

20 Kg

Hourly production rate

20 Kg

Cooling unit

1100 frigories/h

Weight

177 Kg

COMFIT MAXI – Premium Chocolate Coating Machine with Integrated Automatic Spray System

COMFIT MAXI is a high-end chocolate coating machine, specifically designed for chocolate workshops, candy production, and coated nut applications. Built entirely with AISI 304 stainless steel, COMFIT MAXI meets strict hygiene standards, offers exceptional durability, and is easy to maintain—making it the perfect solution for products like chocolate dragees, sugar-coated candies, and more.

Key Features of the COMFIT MAXI Chocolate Coating Machine:

Integrated smart cooling system regulates airflow into the rotating pan, optimizing the drying process to ensure an even, well-adhered chocolate coating.

Polishing technology with thermal resistors delivers a smooth, glossy surface, enhancing the appearance and sensory appeal of every coated piece.

Flexible electronic control panel allows easy temperature adjustments tailored to each product type.

Fast switching between hot and cold air, suitable for various stages of the professional coating process.

Easily removable air filters ensure food safety and simplify maintenance tasks.

COMFIT MAXI + Spray System – The Ideal Duo for Modern Chocolate Coating Lines

When combined with the automatic Spray System, the COMFIT MAXI coating machine offers manufacturers:

Even coating and an attractive finish

Reduced cleaning time and increased production efficiency

A perfect choice for businesses looking to enhance product quality and presentation

COMFIT MAXI with Spray System – a powerful solution for high-performance and professional-grade chocolate coating.

Electrical specification

220 V, 1 phase, 50 Hz

Power required

2,5 Kw – 16 A – 3 poles

Dimensions

(L x W x H)

1060 x 1460 x 1600 mm

Tank capacity

50/60 Kg

Hourly production rate

40 Kg

Cooling unit

1900 frigories/h

Weight

300 Kg

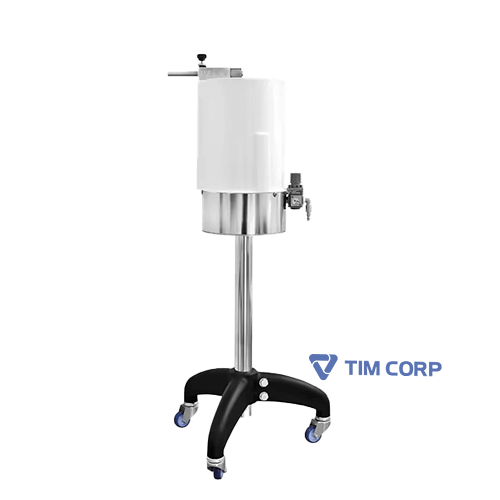

Spray System – Optimized Automatic Spraying System for Chocolate Coating Machines

The Spray System is an optional accessory designed to enhance the chocolate spraying process with greater automation, precision, and consistency:

Specialized spray nozzle heated with low-voltage (LV) power to ensure the chocolate remains in optimal condition during spraying.

Modular mobile design mounted on a stainless steel trolley, allowing easy movement around the production area.

Removable nozzle cap for convenient cleaning and maintenance after each production shift.

Stable automatic spraying, ideal for large-scale production or continuous batch operations.

Compressed air requirement: Pressure 4 atm – Flow rate 350 liters/minute.

Compressed air source

4 atm