What is a Brunner Anliker Vegetable Cutter? Why is it Important in Industrial Kitchens?

The Brunner Anliker vegetable cutter from Switzerland is a professional food processing device, renowned for its exclusive cutting blade technology. The machine not only enables quick and precise slicing, shredding, or chopping of vegetables but also preserves nutrients and fresh flavor. It is the optimal solution for restaurants, hotels, canteens, and food production facilities.

Purpose of Using a Brunner Anliker Machine

- Save Time – Increase Productivity: Process dozens to hundreds of kilograms of vegetables in just a few hours.

- Preserve Nutrients: “Drawing Cut” technology minimizes bruising and keeps the cell structure intact.

- Consistency and Aesthetics: Accurate, visually appealing cuts make dishes more professional.

- Ensure Safety and Hygiene: European-standard design, easy to disassemble and clean, minimizing direct contact.

Why Choose Brunner Anliker?

- Swiss Technology: Precision, durability, certified “Swiss Made.”

- Wide Applications: Suitable for everything from fine dining restaurants to large-scale industrial kitchens.

- High Reliability: Long warranty, outstanding blade lifespan.

- Flexible Productivity: Multiple models available to meet all scales – from dozens of kg/hour to hundreds of kg/hour.

ANLIKER L – Professional Vegetable Cutter for Industrial Kitchens

ANLIKER L is a high-end machine designed for cutting, slicing, and processing vegetables, fruits, cheese, bread, and more – ideal for industrial kitchens, restaurants, catering services, and professional food processing facilities.

Key Features for Vegetable Processing

- “Drawing cut” technology preserves the natural structure of vegetables, minimizes cell damage, and helps retain vitamins and nutrients.

- Composite fiberglass cutting discs offer antibacterial properties, meet HACCP standards, and are dishwasher-safe.

- Handles up to 220 kg of produce per hour, making it suitable for large kitchens and processing workshops.

- 45% larger feed hopper with “Double Shot” insert for efficiently handling long items like cucumbers or carrots.

- No switch required – automatic slide-in design enables fast, safe cutting operations.

- Maintenance-free induction motor and gearbox, backed by a 5-year warranty, meeting Swiss Made standards for durability and quality.

Cleaning & Maintenance

- Key parts such as the feed head, pusher, and cutting discs are dishwasher-safe, making cleaning quick and effortless.

- No need for lubrication or scheduled maintenance – the sealed gearbox and motor ensure long-term stability and performance.

Outstanding Benefits of ANLIKER L

- Saves time & increases productivity: processes up to 220 kg of vegetables per hour with uniform results.

- Hygienic and HACCP-compliant: antibacterial materials and easy cleaning ensure food safety.

- Reduces food waste & preserves freshness by minimizing oxidation during cutting.

- Ergonomic 45° design makes operation comfortable and reduces hand fatigue during extended use.

- 5-year warranty on motor and gearbox – long-term investment with high returns.

Electrical specification

100 - 240 V, 50 - 60 Hz

Motor

0,26 Kw

Dimensions

(W x D x H)

250 x 315 x 540 mm

Weight

19 Kg

Power

220 Kg/h

Protection class

IP 26 water-resistant

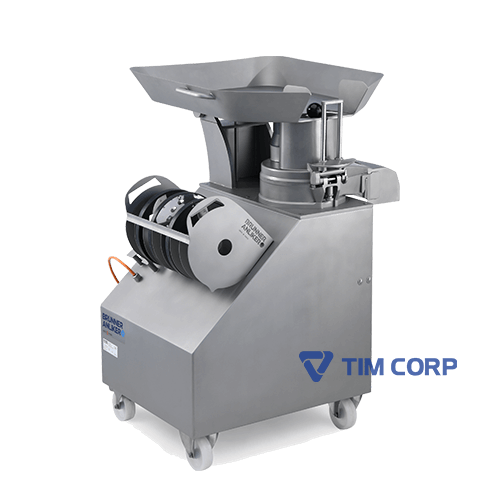

GSM 5 – Professional Vegetable Cutter with Swiss-Made Precision

GSM 5 is a top-tier solution in professional food processing, standing out with its stainless steel construction, intuitive operation, and high-end Swiss Made quality.

Key Advantages

- Proprietary “drawing cut” technology helps retain vitamins and nutrients in vegetables, extending freshness after cutting.

- Offers 50+ cutting styles (slices, sticks, julienne, brunoise, gaufrette, etc.) – suitable for applications ranging from restaurants to large-scale processing centers.

- Antibacterial cutting discs made from composite fiberglass, HACCP-friendly and fully dishwasher-safe.

- Maintenance-free motor and gearbox, with a 5-year warranty – a testament to superior durability.

- Switch-free operation and simple handling mechanism – fully compliant with HACCP, CE, UL, and NSF standards.

- Ergonomic 45° working angle ensures operator comfort and reduces fatigue during long shifts.

Cleaning & Maintenance

- Components such as the feed head, pusher, and cutting discs are 100% dishwasher-safe, ensuring quick and efficient cleaning.

- The main frame only requires wiping with a damp cloth – avoid harsh chemicals or high-pressure washing to maintain machine integrity.

Application Benefits

The GSM 5 Star is optimized for industrial kitchen environments such as:

- Restaurants

- Hotels

- Catering services

- Hospitals

- Cruise ships

- Community kitchens

Where high precision, consistent output, and strict hygiene standards are critical.

Electrical specification

100 - 240 V, 50 - 60 Hz

Motor

0,26 Kw

Dimensions

(W x D x H)

250 x 315 x 540 mm

Weight

23 Kg

Power

Up to 150 Kg/h

Protection class

IP 26 water-resistant

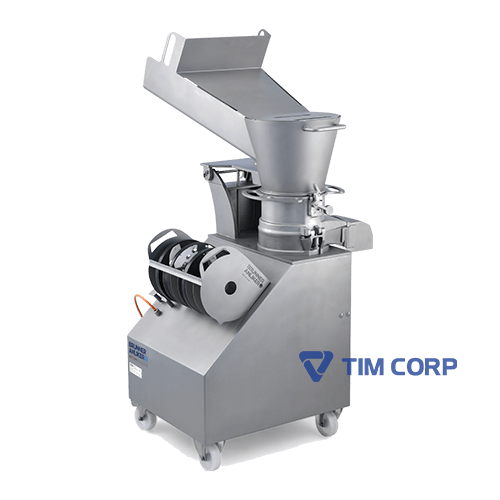

ANLIKER XXL Pro – High-Capacity Vegetable Cutter for Professional Processing Facilities

ANLIKER XXL Pro is a heavy-duty vegetable cutting machine, ideal for high-volume processing environments such as central kitchens, salad bars, industrial food prep, and hospital canteens – where up to 800 kg of vegetables per hour need to be handled efficiently and hygienically.

Key Advantages

- Proprietary “drawing cut” technology helps preserve maximum vitamins and nutrients in vegetables, allowing for longer freshness after cutting.

- Sturdy stainless steel housing, easy to clean; ergonomic design with a large feed hopper that accommodates various vegetable types simultaneously.

- Switch-free operation using a ram pusher system, making the cutting process simple and safe.

- Ceramic-coated cutting discs – scratch-resistant, highly durable, and dishwasher-safe.

- 0.75 kW induction motor (available in 3×400V or 1×115V versions) combined with a maintenance-free gearbox, minimizing long-term operating costs.

- IP x6 protection rating (approx. IP 26) allows for cleaning with water spray at a minimum distance of 0.5 m.

Cleaning & Maintenance

- All removable parts (hopper, pusher, cutting discs) are dishwasher-safe, ensuring quick and hygienic cleaning compliant with HACCP standards.

- The machine’s sealed design means no routine maintenance is required for the motor or gearbox.

Although the machine has a high protection rating, avoid spraying water at closer than 0.5 m, especially with pressure washers.

Electrical specification

3 x 400 V, 50 Hz 1 x 115 V, 60 HZ

Motor

0,75 Kw

Dimensions

(W x D x H)

910 x 725 x 1200 mm

Weight

100 Kg

Power

Up to 800 Kg/h

Protection class

IP 26 water-resistant

ANLIKER XXL – Heavy-Duty Vegetable Cutter for Industrial Food Processing

ANLIKER XXL is a heavy-duty machine ideal for industrial kitchens, catering services, salad bars, hospitals, and airline catering – where large quantities of vegetables (up to 1,500 kg per hour) must be processed with high precision and freshness retention.

Key Highlights

- Exclusive “drawing cut” technology minimizes cell damage, retains vitamins and nutrients, and extends the shelf life of freshly cut produce.

- Robust stainless steel construction – easy to clean and fully HACCP-compliant.

- Flexible cutting options with over 50 different styles: slicing, julienne, brunoise, gaufrette, grating, and more.

- Simple, switch-free operation, mobile with wheels for flexible positioning, ensuring safety and ease of use.

- Ceramic-coated cutting discs – highly resistant to wear and scratches, dishwasher-safe for fast and easy cleaning.

Cleaning & Maintenance

- All removable parts such as the hopper, pusher, and cutting discs are dishwasher-safe, supporting HACCP-standard hygiene.

- Induction motor and sealed gearbox require no regular maintenance – enclosed design reduces wear, lowering long-term operating costs.

Application Benefits

- Outstanding performance – processes large vegetable volumes continuously without compromising quality.

- Hygienic and convenient cleaning, compact disc storage.

- Time-saving and reduced food waste thanks to the gentle cutting method.

- Ergonomic design ensures operator comfort during extended use.

- Swiss-Made durability – a long-term, reliable investment for demanding environments

Electrical specification

3 x 400 V, 50 Hz 1 x 115 V, 60 HZ

Motor

0,75 Kw

Dimensions

(W x D x H)

910 x 1510 x 920 mm

Weight

100 Kg

Power

Up to 1500 Kg/h

Protection class

IP 26 water-resistant