COATING

It is the process of coating a thin, even, and smooth layer of chocolate onto the surface of products such as dried fruits, nuts, pastries, or candies. This is a crucial step that enhances visual appeal, elevates sensory value, and creates a richer taste experience for consumers. Additionally, the chocolate coating helps improve shelf life and opens up opportunities for new product development for businesses in the food industry.

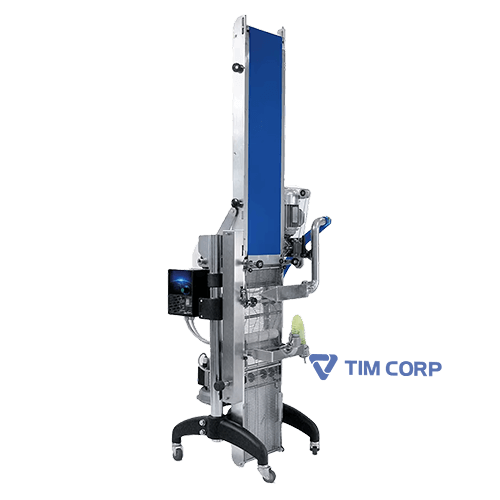

R200 Legend – The Perfect Solution to Elevate Your Product

The Selmi chocolate enrobing machine is the ideal equipment for professional chocolate producers, as well as confectionery and dried fruit businesses looking to expand their product range and elevate the value of existing ingredients.

Key Advantages

Optimal Coating Control

The machine is equipped with a flexible adjustment system that allows precise control over the thickness of the chocolate coating. This ensures a high-quality finish tailored to the specific requirements of each product line.

It can evenly coat chocolate onto a wide variety of ingredients such as:

Dried or frozen fruits

Pastries, candies, nuts, ganache, etc.

Small items as tiny as 10mm or with round or irregular shapes

Complete Coating Support System

Dual tail-cutting rollers: Ensure even chocolate distribution on the bottom of products

Product hold area: Allows temporary pause before coating for precise positioning

Mechanical vibration & electronic air blower: Create a smooth coating layer and minimize chocolate excess

Electronically controlled belt and fan: Easy operation via central control panel

Flexible Design – Easy Integration

Compact structure with castor wheels: Convenient for optimizing production space

Expandable options: Optional accessories available for bottom coating or partial product coating as needed

Compatible with various Selmi tempering machines: including Legend, Plus EX, Futura EX, and Top EX

The Selmi chocolate enrobing machine not only offers production flexibility but also serves as a powerful tool for businesses to:

Develop new products

Enhance visual appeal and sensory value

Optimize processes and improve overall efficiency

Electrical specification

220 V, 1 phase, 50-60 Hz

Power required

0.5 Kw

Dimensions

(L x W x H)

1800 x 410 x 1250 mm

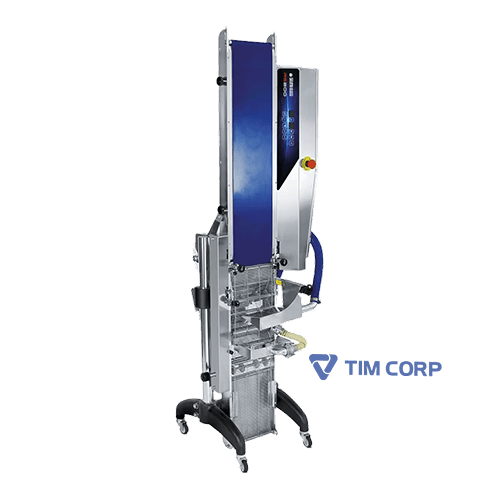

RS200 – The Perfect Solution to Elevate Your Product

The Selmi chocolate enrobing machine is a perfect fit for professional chocolate manufacturers as well as confectionery and dried fruit businesses looking to expand their product range and enhance the value of their existing ingredients.

Key Advantages

Optimal Coating Control

The machine is equipped with a flexible adjustment system, allowing precise control over the thickness of the chocolate coating. This ensures each product line can achieve the desired finish with consistent quality.

Versatile Product Compatibility

The machine can evenly coat a wide range of ingredients, including:

Dried or frozen fruits

Pastries, candies, nuts, ganache, and more

Small items starting from just 10mm, even with round or irregular shapes

Complete Coating Support System

Dual tail-cutting rollers: Distribute chocolate evenly on the underside of the product

Ingredient feed pause zone: Pauses product flow just before coating to precisely position items

Mechanical vibration and electronic air blowers: Ensure uniform coating and reduce excess chocolate

Electronic conveyor and air fan control: Easy to operate via central control panel

Flexible Design – Easy to Integrate

Foldable frame with wheels: Convenient for optimizing production space

Expandable options: Add-ons available for bottom-only or partial coating as needed

Compatible with various Selmi tempering machines: Including Legend, Plus EX, Futura EX, and Top EX

The Selmi chocolate enrobing machine not only brings flexibility to your production line but also serves as a powerful tool to help businesses:

Develop new product lines

Enhance visual appeal and sensory value

Optimize workflows and improve production efficiency

Electrical specification

220 V, 1 pha, 50-60 Hz

Power required

0,5 Kw - 16A - 3 poles

Unfolded dimensions

(D x W x H)

600 x 1800 x 1200 mm

Folded dimensions

(D x W x H)

600 x 600 x 1800 mm

Truffle Chocolate Machine – Automating the Process, Elevating Quality

The truffle chocolate machine is the ideal solution for premium chocolate workshops aiming to optimize the truffle-making process—from chocolate coating to final outer layering—with precision, speed, and consistency.

This machine eliminates the common drawbacks of manual production: ingredient loss, high labor demand, inconsistent results—while ensuring superior hygiene standards and operational efficiency.

Key Advantages of the Truffle Chocolate Machine

Automatic coating and shaping of truffles using a dual-zone conveyor system: one for feeding and one for chocolate coating, with integrated vibration and air blowers for precise coating control.

Automatic vibrating chute gently guides truffles after coating, delivering perfectly shaped, uniform products.

Compact and clean operation, requiring only one or two operators.

Easy to disassemble and clean, making it suitable for both small workshops and mid-sized factories.

Why Choose a Truffle Chocolate Machine Over Manual Production?

Save time & labor – Replace multiple manual steps with an automated process that only requires one or two operators.

Consistent quality – Each truffle is coated precisely and attractively, giving your product a professional finish.

Enhanced hygiene & safety – Automation minimizes hand contact, aligning with food safety standards.

Boost production capacity – Perfect for businesses aiming to scale up while maintaining artisanal quality.

Truffle Chocolate Machine – A Strategic Investment for Chocolate Businesses

In the premium chocolate industry, truffles are a product line that carries significant brand value. Investing in a truffle chocolate machine not only enhances your final product quality but also optimizes costs, increases competitiveness, and strengthens your market expansion potential.

Electrical specification

220 V, 1 phase, 50-60 Hz

Power required

0,16 Kw – 16 A – 3 poles

Dimensions

(L x W x H)

1700 x 1350 x 1470 mm

Hourly production rate

30 Kg/h