REFINING

After coarse grinding, the cacao liquor must undergo fine grinding to achieve the ideal smoothness, giving the chocolate a silky texture with a particle size of 20–25 microns.

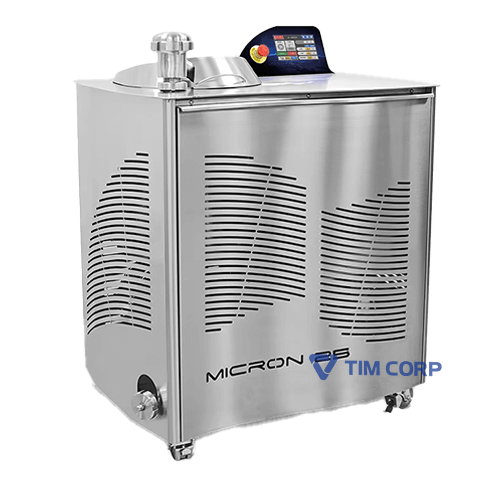

SELMI MICRON 25 Ball Refiner – Professional Fine Grinding Solution for Chocolate and Nut Butters

The Selmi ball refiner is a premium machine specifically engineered for the fine grinding of chocolate, as well as for producing smooth-textured products such as spreadable creams, praline fillings, and water-free mixtures used in premium ice cream and confectionery.

Precision Grinding – Preserving Natural Flavor

Equipped with an automatic cooling system, the machine efficiently controls heat generated by friction between the grinding balls. This keeps the temperature stable throughout the process, preserving the ingredient’s key sensory properties—aroma, color, and texture—which are crucial for high-quality artisanal chocolate production.

Smart Operation – Consistent Performance

The refiner features a dual-function volumetric pump that continuously circulates the mixture during operation. This ensures even mixing and a uniform, fine grind, resulting in consistent quality across batches.

Additionally, the grinding cylinder is gently heated to prevent fat solidification between the balls during temporary pauses. This feature supports uninterrupted operation and enhances overall efficiency.

Versatile Applications – Perfect for Various Production Models

The Selmi ball refiner is ideal not only for Bean to Bar chocolate workshops, but also for businesses producing nut butters or innovative chocolate-based products that demand a smooth and uniform texture.

The Selmi Micron 25 is a technological advancement that significantly enhances product quality in chocolate making and premium food processing.

Electrical specification

400 V, 3 phases, 50 Hz

Power required

4 Kw – 16A – 5 poles

Dimensions

(L x W x H)

1200 x 750 x 950 mm

Tank capacity

20 - 25 Kg

Refining time

15 - 20 Kg/h

Compressed air source

350 lt/min - 6 bar minimum - filtered, dry, deoiled

Weight

290 Kg

Metal balls volume

70 Kg

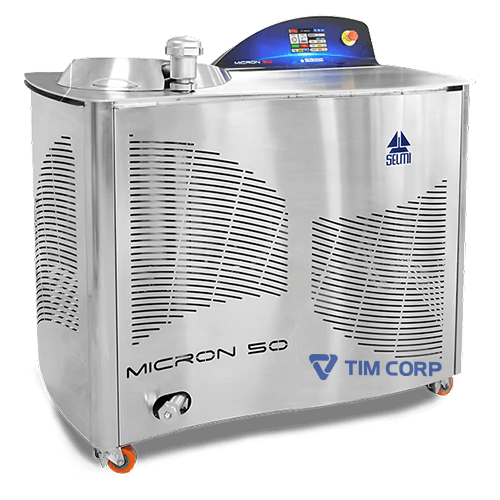

SELMI MICRON 50 Ball Refiner – Fine Grinding Solution for Chocolate, Spreads, and Praline Fillings

The Selmi ball refiner is a specialized machine designed for the fine grinding of chocolate, the production of spreadable creams, water-free mixtures for ice cream, and premium praline fillings. It is the ideal solution for artisan chocolate makers and high-end food producers.

Flavor Preservation – Protecting the Sensory Integrity of Ingredients

Equipped with an automatic cooling system, the machine precisely controls the heat generated by friction during the grinding process. The temperature remains stable within preset limits, helping preserve the essential qualities of the raw materials—aroma, taste, and color—which are critical in the production of fine chocolate.

Continuous Operation – Consistent Smoothness and Texture

Thanks to its dual-function volumetric pump, the mixture is continuously circulated during grinding, ensuring a uniform and smooth texture throughout. Additionally, the grinding cylinder is kept gently warmed, preventing fat solidification during temporary pauses and ensuring uninterrupted operation and product consistency.

The Selmi Micron 50 not only optimizes production efficiency but also helps businesses significantly elevate the quality of their finished products.

Electrical specificaction

400 V, 3 phases, 50 Hz

Power required

12 Kw – 32 A – 5 poles

Dimensions

(L x W x H)

1400 x 840 x 1320 mm

Tank capacity

60 Kg

Refining time

40 Kg/h

Compressed air source

350 lt/min - 6 bar minimum - filtered, dry, deoiled

Weight

760 Kg

Metal balls volume

220 Kg

SELMI MICRON 100 Ball Refiner – High-Capacity Fine Grinding Solution for Chocolate

If you’re looking for a high-performance ball refiner to elevate your chocolate or spreadable cream production line, the Selmi MICRON 100 is your top choice. Specifically designed for large-scale production, MICRON 100 delivers the perfect balance of output, fineness, and flexibility.

Impressive Output – Compact Size

The Selmi MICRON 100 can process up to 100 kg of product in just 1 hour and 20 minutes, all while maintaining a compact footprint that fits easily into any production space. It’s the ideal solution for high-volume producers who need maximum efficiency without sacrificing floor space.

Advanced Fine Grinding Technology

Engineered for professional chocolate production, MICRON 100 utilizes stainless steel grinding balls in combination with:

A continuous lobe pump circulation system to ensure optimal product uniformity

A dual-compartment tank with double-layer heating, allowing precise temperature control to protect flavor and texture

A warm-maintenance feature in the grinding cylinder to prevent fat solidification during operation pauses

Smart Control Interface

The machine comes with a modern digital control panel, offering:

Customization of the process in both manual and automatic modes

Recipe storage for easy batch replication with high accuracy

Reliable delivery of perfect fineness while preserving the sensory quality of the final chocolate

Why Choose the Selmi MICRON 100 Ball Refiner?

Perfectly suited for large-scale production

Increases efficiency without compromising product quality

Easy to operate, maintain, and integrate into Bean to Bar workflows

Long-term investment value with durability and stable performance

The Selmi MICRON 100 is the ultimate solution for manufacturers aiming to scale up while maintaining the artisanal quality that sets their products apart.

Electrical specification

400 V, 3 phases, 50 Hz

Power required

15 Kw – 32 A – 5 poles

Dimensions

(L x W x H)

1073 x 1619 x 1482 mm

Tank capacity

100 Kg

Refining time

70 Kg/h

Weight

1200 Kg