BRUNNER ANLIKER XXL HIGH-CAPACITY VEGETABLE CUTTER

Electrical supply

3×400 V, 50Hz 1×115 V, 60Hz

Power

0,75Kw

Processing capacity

1500 kg/h

Feed hopper opening

198 x 140 mm

Dimensions (W × D × H)

910 x 1510 x 920 mm

Weight

100 Kg

PRODUCT DETAILS

1. OVERVIEW

Brand: Brunner Anliker – Switzerland

Application segment: Industrial vegetable cutting equipment for central kitchens, catering systems, hospitals, airlines, food factories, and large-scale meal production facilities.

Device introduction:

ANLIKER XXL is a heavy-duty industrial vegetable cutter engineered for central kitchens, catering systems, salad bars, hospitals, and airline catering where extremely high processing capacity is required.

It handles up to 1,500 kg/hour while maintaining excellent freshness and cutting precision.

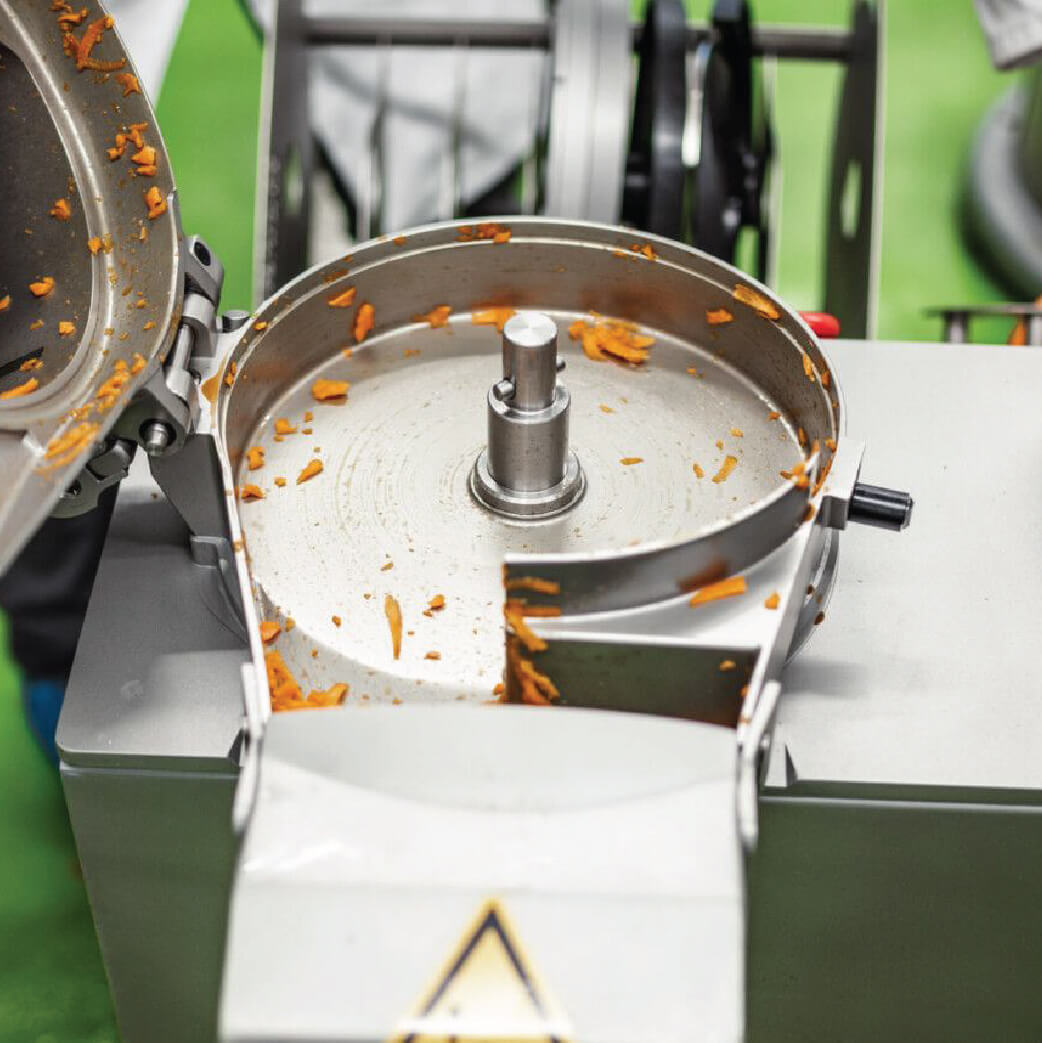

Equipped with the exclusive “Drawing Cut” technology, ANLIKER XXL reduces cell damage, preserves vitamins and minerals, and maintains natural flavor.

Its HACCP-grade stainless-steel construction ensures hygiene, easy cleaning, and safe operation – a hallmark of Swiss Made quality.

2. KEY FEATURES

“Drawing Cut” technology – Smooth cutting while preserving nutrients

Soft sliding cuts prevent crushing, maintaining structure and nutritional integrity.

Minimizes oxidation, extending freshness after cutting.

Ultra-high performance – Versatile cutting options

Processes up to 1,500 kg/hour, ideal for large-scale production environments.

Supports more than 50 cutting styles: thin slices, julienne, brunoise, gaufrette, grating, etc.

Ceramic-coated cutting discs resist wear, are easy to clean, and dishwasher-safe.

Industrial design – Safe and convenient

Robust 304 stainless-steel body, suitable for continuous heavy-duty operation.

Operates without mechanical switches for absolute safety.

Equipped with wheels for easy mobility in processing areas.

Ergonomic design with optimized working angles reduces user fatigue.

Easy cleaning & low maintenance

All removable parts such as hopper, pusher, and cutting discs are dishwasher-safe.

Induction motor and sealed gearbox require no maintenance, lowering long-term costs.

3. INVESTMENT BENEFITS

Exceptional productivity: handles up to 1,500 kg/hour for large-scale operations.

Ensures food safety: stainless-steel construction, HACCP compliant.

Boosts efficiency and saves time: accurate, consistent, high-speed cutting.

Reduces food waste: gentle cutting helps maintain freshness longer.

Durable long-term investment: Swiss Made design with long-life motor and gear unit.

4. TECHNICAL SPECIFICATIONS

Specification | Value |

Model | ANLIKER XXL |

Electrical Supply | 3×400 V, 50 Hz / 1×115 V, 60 Hz |

Motor Power | 0.75 kW |

Processing Capacity | 1,500 kg/h |

Cutting Disc Diameter | Ø 240 mm |

Protection Class | IP x6 – High-pressure water resistant |

Dimensions (W × D × H) | 910 × 1,510 × 920 mm |

Weight | 100 kg |

Feed Hopper Opening | 198 × 140 mm |

Body Material | Inox 304 – Stainless Steel |

Cutting Material | Ceramic-coated, dishwasher-safe |

Warranty | 5 years for motor & gearbox |

Origin | Switzerland |

BRUNNER ANLIKER XXL PRO HIGH-CAPACITY VEGETABLE CUTTER

Electrical supply

3×400 V, 50Hz 1×115 V, 60Hz

Power

0,75Kw

Processing capacity

800 Kg/h

Feed hopper opening

103 x 86 mm

Dimensions (W × D × H)

910 x 725 x 1200 mm

Weight

100 Kg

PRODUCT DETAILS

1. OVERVIEW

Brand: Brunner Anliker – Switzerland

Application segment: Industrial vegetable cutting equipment for central kitchens, salad bars, food processing facilities, hospital kitchens, cruise ships, catering operations, and large-scale meal production systems.

Device introduction:

ANLIKER XXL Pro is a heavy-duty industrial vegetable cutter developed specifically for central kitchens, salad bars, food processing units, hospital kitchens, and large-scale industrial kitchens that require high-volume processing up to 800 kg/hour while maintaining cutting precision and high product quality.

Inherited from Brunner Anliker’s exclusive “Drawing Cut” technology, the machine preserves vitamins, nutrients, and natural freshness of vegetables, while minimizing food loss during processing.

Built with premium 304 stainless steel, a maintenance-free induction motor, and a sealed gearbox, the ANLIKER XXL Pro delivers durable performance and Swiss Made reliability.

2. KEY FEATURES

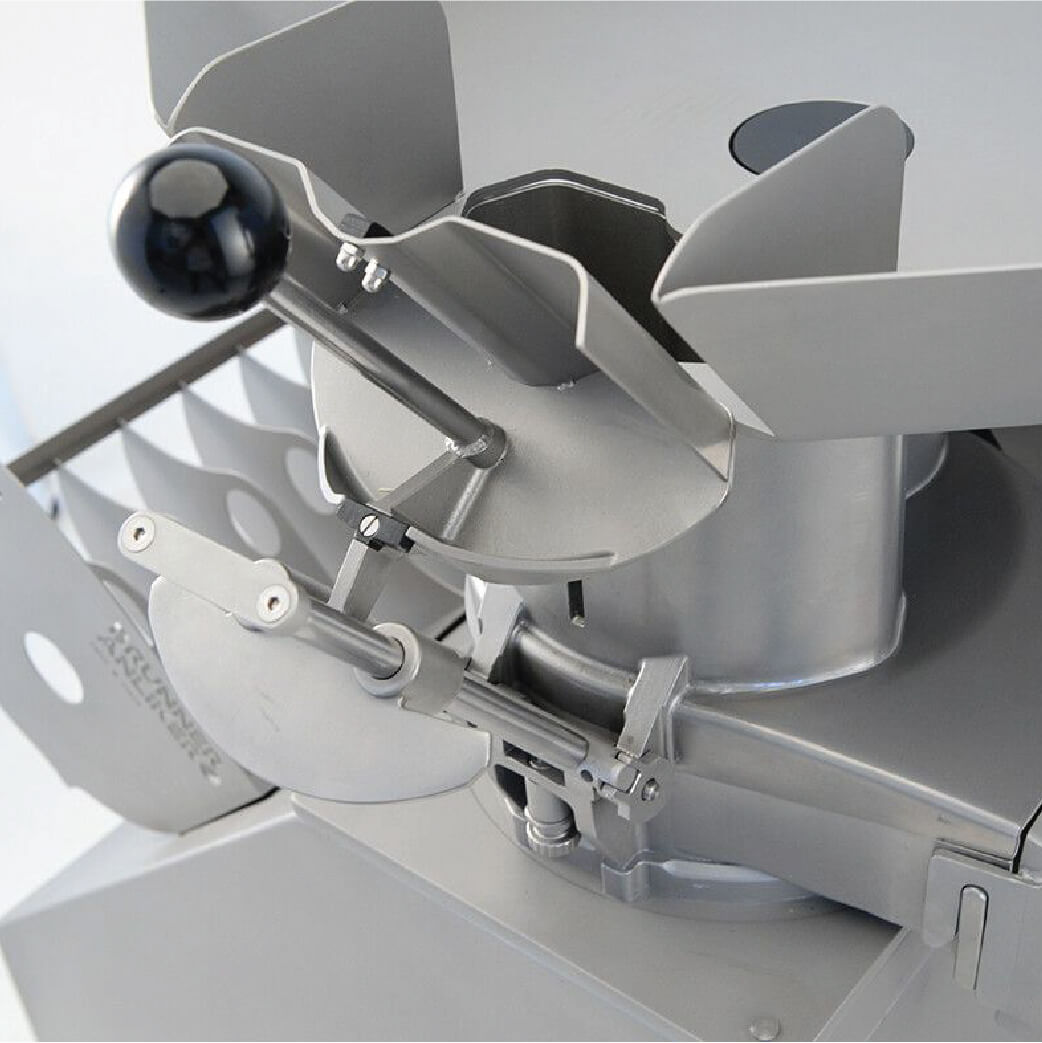

“Drawing Cut” technology – Preserves natural integrity

Exclusive sliding cut mechanism minimizes cell damage and retains the maximum amount of vitamins and nutrients.

Vegetables stay fresh longer, maintain natural color, and do not bruise or release excess moisture.

Powerful performance – Superior durability

Processes up to 800 kg/hour, ideal for large-scale production environments.

Ceramic-coated cutting discs are scratch-resistant, wear-resistant, and dishwasher-safe.

Equipped with a 0.75 kW induction motor paired with a sealed gearbox that requires no maintenance.

User-friendly design – Safe and ergonomic

Robust 304 stainless-steel housing, easy to clean, HACCP compliant.

Operates without mechanical switches, using a ram system for fast and extremely safe cutting.

Large feed hopper allows processing multiple types of vegetables simultaneously.

Ergonomic design with ideal working height reduces fatigue during long working shifts.

High protection level – Easy cleaning

IP x6 protection rating allows cleaning with a water jet from a distance of ≥ 0.5 m.

All removable parts (pusher, hopper, cutting discs) are dishwasher-safe.

Zero maintenance required for motor or gearbox, reducing operating costs and extending lifespan.

3. INVESTMENT BENEFITS

Optimized productivity: processes up to 800 kg/h, ideal for industrial kitchens and processing lines.

Retains full nutrition: prevents bruising and preserves natural color and flavor.

Absolute hygiene and safety: HACCP, CE, UL, NSF compliant.

Reduced maintenance cost: sealed motor and gearbox require no periodic servicing.

Fast cleaning and easy operation: smart design with dishwasher-safe parts.

Sustainable investment: Swiss Made quality with long-term precision and durability.

4. TECHNICAL SPECIFICATIONS

Specification | Value |

Model | ANLIKER XXL Pro |

Electrical Supply | 3×400 V 50 Hz / 1×115 V 60 Hz |

Motor Power | 0.75 kW |

Processing Capacity | 800 kg/h |

Cutting Disc Diameter | Ø 240 mm |

Protection Class | IP x6 – High-pressure water resistant (≥ 0.5 m) |

Dimensions (W × D × H) | 910 × 725 × 1,200 mm |

Footprint | 366 × 275 mm |

Weight | 100 kg |

Feed Hopper Opening | 103 × 86 mm |

Hopper Height | 152 mm |

Body Material | Inox 304 – Stainless Steel |

Cutting Material | Ceramic-coated, dishwasher-safe |

Warranty | 5 years for motor & gearbox |

Origin | Switzerland |