OEM BM2AS DOUGH DIVIDER & ROUNDING MACHINE

Electrical supply

400 V/3 Pha/50 Hz

Power

0.84 Kw

Weight

182 Kg

Hopper Capacity

30 Kg

Dimensions (WxDxH)

765x765x1450 mm

PRODUCT DETAILS

1. OVERVIEW

Brand: OEM – Italy

Application Segment: Bakery / Pizza / Horeca / Central Kitchen

Equipment Introduction:

The OEM BM2AS is a semi-industrial dough dividing and rounding machine imported directly from Italy, designed for bakeries, pizzerias, and central kitchens requiring fast, stable, and precise production.

The machine combines two functions in one – dough weighing/dividing and automatic rounding – significantly saving time and labor while ensuring uniform dough pieces.

With a hopper capacity of 30 kg, a dividing range of 50–300 g, and a throughput of 700–1,200 pieces/hour, the BM2AS perfectly meets the needs of medium to large-scale production facilities.

OEM BM2AS is officially distributed by TIM Corp in Vietnam, with professional consulting, installation, and maintenance services.

2. KEY FEATURES

Two Functions in One: Automatic dough dividing and rounding – simplifies workflow and boosts productivity.

Large Hopper Capacity: 30 kg, compatible with most standard mixing bowls used in pizzerias and central kitchens.

Flexible Dividing Range: 50–300 g per piece, suitable for bread, pizza, dough balls, or natural leaven dough portions.

High Throughput: Up to 1,200 pieces/hour with weight deviation < 10%, saving manual labor.

Durable Construction: Powder-coated steel body, stainless steel contact parts – easy to clean and smooth operation.

Optional Rounding Head: Customers can select bell (rounding bell) or cone (dividing cone) according to desired weight when ordering.

3. INVESTMENT BENEFITS

Reduces manual labor, accelerates dough dividing and rounding processes.

Ensures uniform weight and shape of each dough piece.

Increases overall productivity and product consistency.

Easy to clean and maintain, suitable for continuous operation environments.

Meets European standards and compatible with professional HACCP workflows.

4. TECHNICAL SPECIFICATIONS

Specification | Value |

Electrical Supply | 400 V / 3 Phase / 50 Hz |

Power Input | 0.84 kW |

Hopper Capacity | 30 kg |

Dimensions (WxDxH) | 765 × 765 × 1450 mm |

Net Weight | 182 kg |

Special Features | Integrated dough dividing & rounding |

Origin | Italy |

ESMACH DVMACH EVO 400V TRI+T 50Hz DOUGH DIVIDER

Electrical supply

400 V TRI+T 50 Hz

4.6 A|3 Pha|Gn

Power

1.8 Kw

Weight

380 Kg

Dough capacity

(min/max)

4 / 20 Kg

Weight of dough pieces

(min/max)

400/2000 g (10 viên)

200/1000 g (20 viên)

Dimensions (WxDxH)

765x765x1450 mm

PRODUCT DETAILS

1. OVERVIEW

Brand: Esmach – Italy

Application Segment: Bakery / Pizza / Artisan Bread Production / Industrial Kitchen

Equipment Introduction:

The Esmach DVMACH EVO 400V TRI+T 50 Hz is an automatic hydraulic dough divider specifically designed for production lines making bread, pizza, and artisan dough products, where speed, precision, and stability are essential.

This machine can divide up to 20 kg of dough per cycle, producing 10 or 20 uniform dough pieces in a single operation.

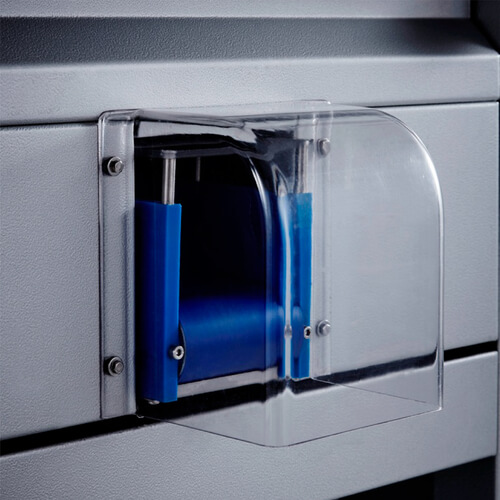

Its powder-coated steel frame, stainless steel bowl and cutting blades, and polyethylene cover ensure durability, safety, and hygiene in industrial kitchen environments.

The “stop & go” hydraulic system controlled by a microprocessor optimizes the operation cycle, reduces oil temperature, and extends equipment lifespan.

Esmach DVMACH EVO is officially distributed by TIM Corp in Vietnam, offering full consulting, installation, training, and professional maintenance services.

2. KEY FEATURES

Fast & Accurate Dividing: One cycle divides up to 20 kg of dough into 10 or 20 uniform pieces.

Automatic Hydraulic Technology: “Stop & go” microprocessor-controlled system ensures smooth operation and reduced oil temperature.

Durable Construction: Powder-coated steel frame, stainless steel bowl and blades, polyethylene cover – hygienic and long-lasting.

Central Control Panel: Clear function buttons for simple and safe operation.

Flexible Dough Piece Sizes: 10-piece grid (400–2000 g) or 20-piece grid (200–1000 g); optional smaller divisions available.

High Throughput: 900–1,250 pieces/hour – suitable for continuous production.

Easy Mobility: Equipped with safety lock wheels for convenient maintenance and positioning.

3. INVESTMENT BENEFITS

Increases dough dividing speed and reduces manual labor.

Ensures uniform weight and shape of dough pieces.

Maintains consistent product quality during continuous production.

Easy to maintain, clean, and operate safely.

Suitable for large bakeries, industrial kitchens, and professional factories.

4. TECHNICAL SPECIFICATIONS

Specification | Value |

Electrical Supply | 400 V / 3 Phase / 50 Hz |

Power Input | 1.8 kW / 4.6 A |

Dimensions (WxDxH) | 820 × 890 × 1140 mm |

Weight | 380 kg |

Dough Capacity | 4 – 20 kg |

Weight of dough pieces | – 400/2000 g (10 pieces) – 200/1000 g (20 pieces) |

Origin | Italy |