Selmi TANK 200 - Chocolate Melting and Mixing Machine

Voltage

400 V/1 Phase/ 50 Hz

Power consumption

4000 W

Tank capacity

200 Kg

Weight

380 Kg

Dimensions

(LxWxH)

880x1000x1350 mm

DETAILED PRODUCT INFORMATION

1. OVERVIEW

Brand: Selmi – Italy

Application Segment: Designed for Bean-to-Bar chocolate workshops, medium- to large-scale production facilities, and artisanal manufacturers requiring stable melted chocolate preparation.

Equipment Introduction:

- The Selmi Tank 200 is a dedicated system for melting and maintaining chocolate in a stable liquid state during preparation and production.

- With a 200 kg tank capacity, it provides continuous heating, mixing, and homogenization of chocolate mass, ensuring it remains at the ideal temperature and texture before being pumped into tempering, moulding, or enrobing lines.

- Manufactured entirely in AISI 304 stainless steel, the Tank 200 meets the highest European food safety and hygiene standards. It is durable, easy to clean, and built for stable performance in industrial environments.

2. KEY FEATURES

Uniform Heating and Mixing – Stable Chocolate Quality

- Indirect heating system combined with a central agitator ensures smooth, even melting without burning or cocoa butter separation.

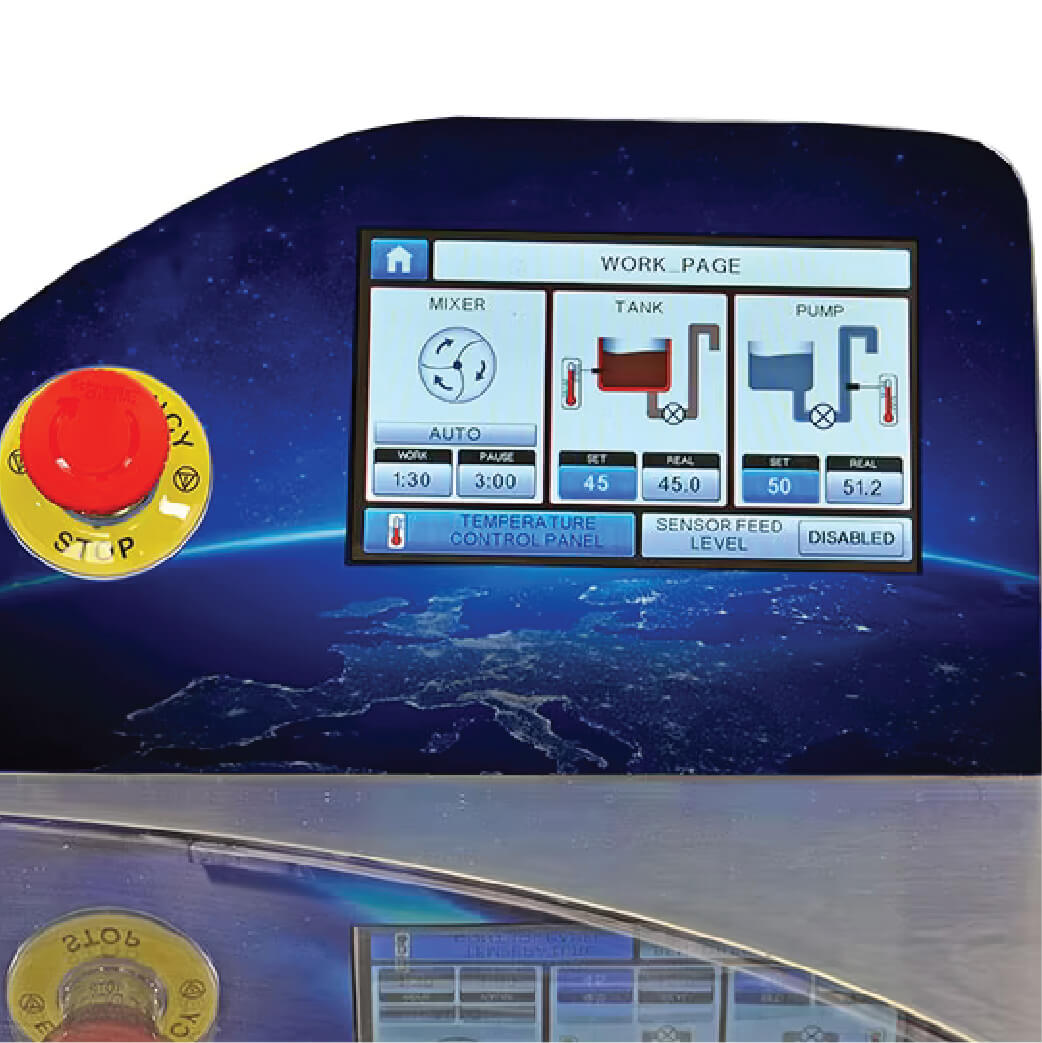

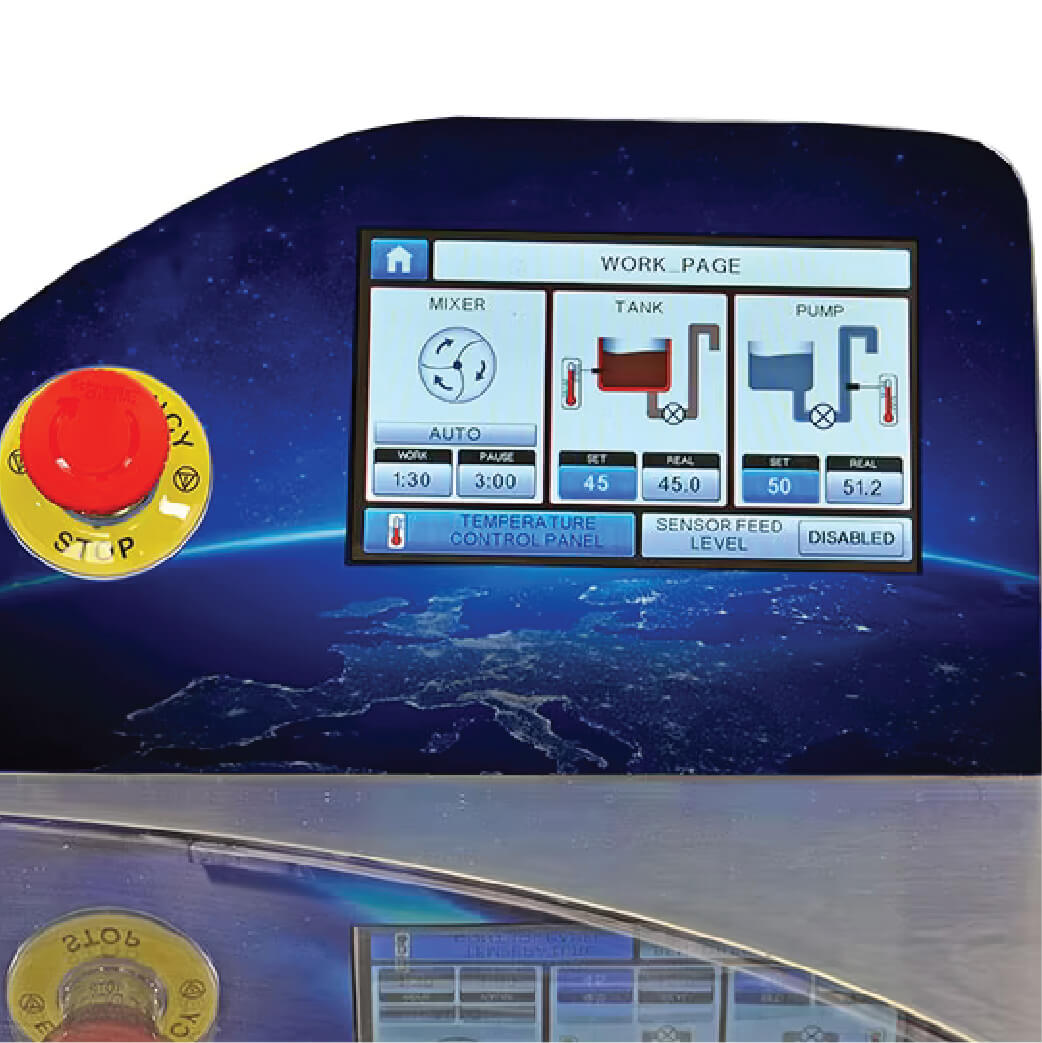

- High-precision temperature sensors maintain consistent heat throughout operation, preserving the chocolate’s natural aroma and structure.

Smart Design – Flexible Integration

- Chocolate outlet can be positioned on the left or right side, adaptable to the production layout for easy connection with tempering or pumping systems.

- Large opening and deep tank simplify ingredient loading, inspection, and cleaning.

Industrial Construction – Long-Term Reliability

- Full AISI 304 stainless-steel structure guarantees durability, corrosion resistance, and food-grade compliance.

- Solid block frame (380 kg) minimizes vibration and ensures stable performance during continuous operation.

3. INVESTMENT BENEFITS

- Maintains optimal chocolate quality – always smooth, fluid, and ready for the next production phase.

- Increases operational efficiency – large 200 kg capacity allows continuous preparation with minimal downtime.

- Flexible installation – integrates easily with Selmi tempering, depositing, or enrobing machines.

- Hygienic and low-maintenance design reduces cleaning time and extends equipment lifespan.

4. TECHNICAL SPECIFICATIONS

Specification | Value |

Electrical Specification | 400 V / 3 ph / 50 Hz |

Power Required | 4 kW – 16 A – 5 poles |

Tank Capacity | 200 kg |

Dimensions L×W×H | 880 × 1000 × 1350 mm |

Empty Weight | 380 kg |

Extraction of Chocolate | Left or right side (defined before order) |

Construction | Entirely in AISI 304 stainless steel |

Origin | Italy |

Selmi TANK 400 - Chocolate Melting and Mixing Machine

Voltage

400 V/3 Phase/ 50 Hz

Power consumption

5000 W

Tank capacity

350 Kg

Weight

573 Kg

Dimensions

(LxWxH)

880x1000x1350 mm

DETAILED PRODUCT INFORMATION

1. OVERVIEW

Brand: Selmi – Italy

Application Segment: Designed for large-scale chocolate factories, Bean-to-Bar production lines, and high-output artisanal facilities.

Equipment Introduction:

- The Selmi Tank 400 is a large-capacity melting and mixing unit (350 kg) engineered to heat, homogenize, and maintain chocolate in a stable liquid state throughout production.

- It is the ideal solution for facilities that require continuous large-volume chocolate preparation prior to tempering, moulding, or enrobing stages.

- Built entirely from AISI 304 stainless steel and equipped with high-precision temperature control, the Tank 400 ensures consistent texture, gloss, and flavor — meeting the highest standards of the European chocolate industry.

2. KEY FEATURES

Even Heating – Preserved Chocolate Flavor

- Indirect heating system guarantees smooth melting without scorching or fat separation.

- Integrated thermal sensors and automatic control maintain precise temperature stability throughout the cycle.

Smart Automation – Safe Material Feeding

- Equipped with a Sensor Feed system that detects and adjusts chocolate levels automatically, preventing overflow or shortages for safe and stable operation.

- Central agitator continuously stirs the mass, ensuring uniform consistency and readiness for the next phase.

Industrial Design – Flexible Installation

- Chocolate outlet can be positioned on either the left or right side, adaptable to production layouts.

- Heavy-duty frame (573 kg) ensures vibration-free performance and long-term durability in continuous operations.

- Wide opening for easy access during cleaning, inspection, and maintenance.

Food-Grade Materials – Long Lifespan

- Constructed entirely in AISI 304 stainless steel, offering corrosion resistance and heat durability.

- Fully compliant with international food-safety standards and built for long-term industrial use.

3. INVESTMENT BENEFITS

- Optimizes production workflow – provides a large, stable supply of liquid chocolate ready for all downstream processes.

- Minimizes operational risks – automatic feed sensor prevents overflow or empty tank conditions.

- Saves time and labor – continuous operation and easy integration with Selmi tempering, depositing, enrobing, or recirculation systems.

- Improves final product quality – stable temperature control ensures glossy, smooth, and uniform chocolate.

- Meets European manufacturing standards – AISI 304 stainless steel construction, precision engineering, and long equipment lifespan.

4. TECHNICAL SPECIFICATIONS

Specification | Value |

Electrical Specification | 400 V / 3 ph / 50 Hz |

Power Required | 5 kW – 16 A – 5 poles |

Tank Capacity | 350 kg |

Dimensions L×W×H | 880 × 1000 × 1350 mm |

Empty Weight | 573 kg |

Extraction of Chocolate | Left or right side (specified at order) |

Construction | Entirely in AISI 304 stainless steel |

Included Sensor Feed | Italyes |

Origin | Italy |