SELMI CONCA 100 - Conching machine

Voltage

400 V,3 phase ,50 Hz

Power consumption

4 Kw–16 A–5 poles

Dimensions

(LxWxH)

620x710x1200 mm

Tank capacity

100 Kg

DETAILED PRODUCT INFORMATION

1. OVERVIEW

Brand: Selmi – Italy

Application Segment: Bean-to-Bar chocolate production lines, artisanal and industrial chocolate processing facilities.

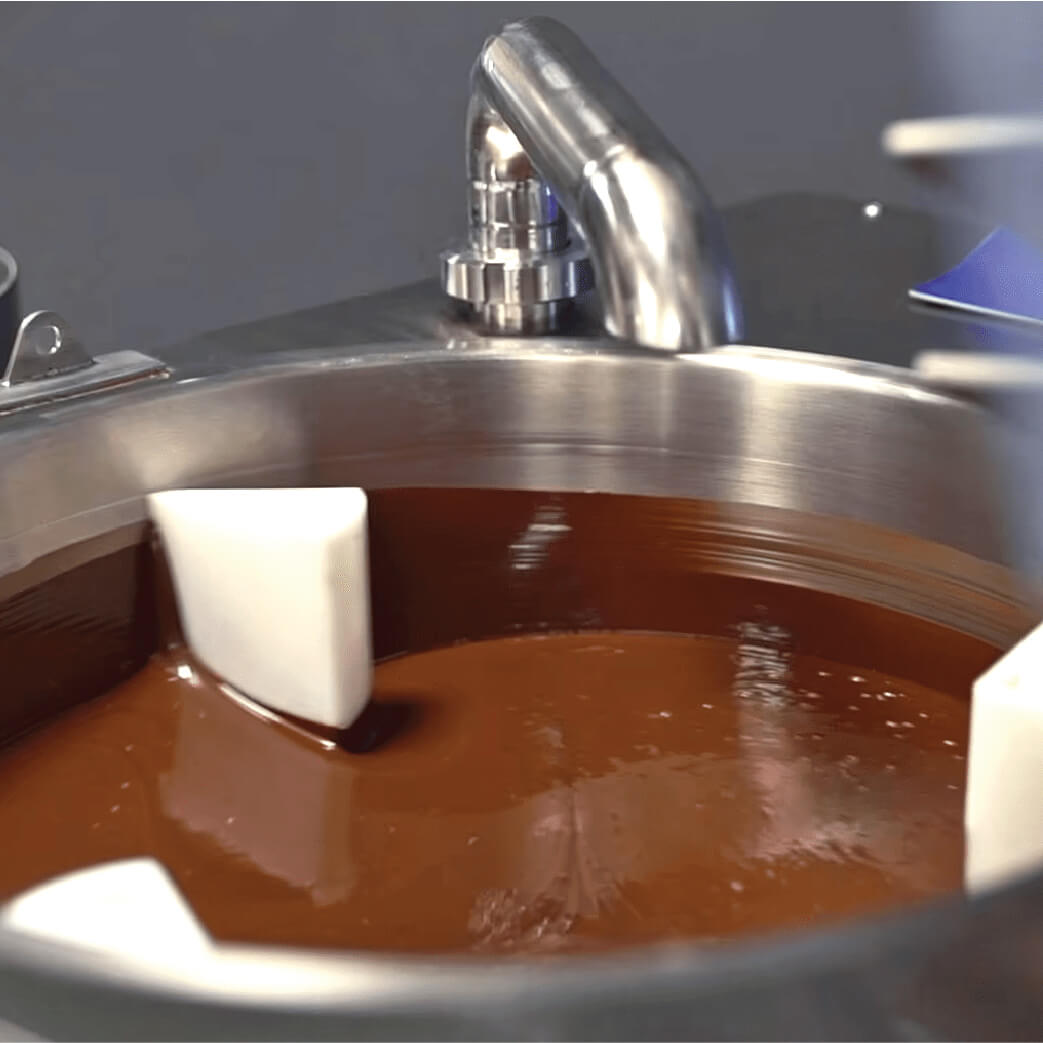

Equipment Introduction:

- The Selmi Conca 100 is an essential machine in professional chocolate production lines, responsible for the conching stage – a key process that removes acidity, bitterness, and residual moisture from chocolate mass.

- Designed with a mixing arm positioned inside a heated tank, the Conca 100 continuously stirs the chocolate mass for 8–12 hours, creating the ideal conditions for oxidation and flavor development.

- The result is a chocolate with superior smoothness, rich aroma, and a perfectly balanced structure.

- The advanced touch-screen control panel allows operators to set and monitor four key parameters – time, temperature, emulsification, and oxidation airflow – ensuring precise control over every recipe.

2. KEY FEATURES

Precision Conching – Enhanced Chocolate Flavor

- Eliminates residual acidity, bitterness, and moisture.

- Improves smoothness, gloss, and structural uniformity.

- Increases product stability and shelf life.

Smart Control – Customizable Operation

- Intuitive touch-screen interface with easy parameter setup.

- Adjustable and storable settings for time, temperature, emulsification, and oxidation.

- Enables precise flavor control for each chocolate formulation.

Optimized Design – Durable and Efficient

- Heated tank ensures consistent and even temperature distribution.

- Sturdy stainless-steel construction for hygiene and easy maintenance.

- Quiet operation, energy-efficient performance, ideal for medium to large workshops.

3. INVESTMENT BENEFITS

- Ensures premium sensory quality – smooth, balanced, and rich chocolate flavor.

- Full control over the conching process – the decisive factor in flavor identity.

- Reduces labor time and ingredient loss.

- Easily integrates into Selmi Bean-to-Bar production lines.

- Increases product value, meeting international artisanal chocolate standards.

4. TECHNICAL SPECIFICATIONS

Specification | Value |

Electrical Specification | 400V / 3 ph / 50 Hz |

Power Required | 4 kW – 16 A – 5 poles |

Tank Capacity | 100 kg |

Dimensions L×W×H | 625 × 920 × 1200 mm |

Origin | Italy |

SELMI CONCA 200 - Conching machine

Voltage

400 V,3 phase ,50 Hz

Power consumption

4 Kw–16 A–5 poles

Dimensions

(LxWxH)

620x710x1460 mm

Tank capacity

200 Kg

DETAILED PRODUCT INFORMATION

1. OVERVIEW

Brand: Selmi – Italy

Application Segment: Artisanal Bean-to-Bar chocolate production

Equipment Introduction:

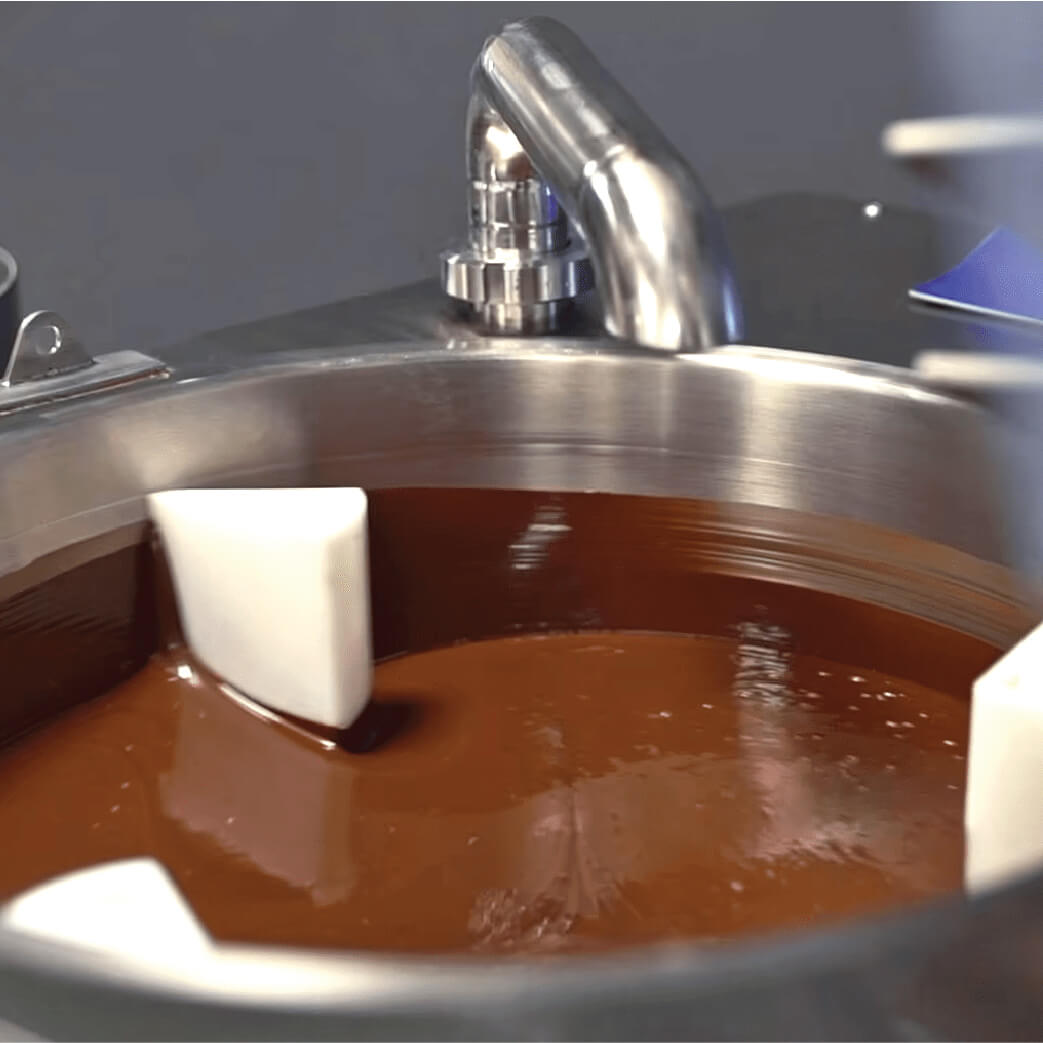

- The Selmi Conca 200 is a professional-grade chocolate conching system, playing a central role in Bean-to-Bar production.

- It completely removes residual acidity and moisture while developing the chocolate’s natural aroma, smooth texture, and glossy finish.

- Featuring a central-shaft mixing system inside a heated tank, the Conca 200 operates continuously for 8–12 hours, achieving total uniformity and flavor depth in every batch.

- With its 200 kg capacity, this model is ideal for professional chocolate producers targeting international-level standards.

2. KEY FEATURES

Flavor Optimization – Eliminates Acidity and Moisture

- Extended conching (8–12 hours) balances flavor and removes volatile acids and moisture.

- Controlled oxidation enhances the chocolate’s natural aroma and depth of flavor.

Dual-Inertia Mixing Technology – Superior Homogeneity

- Dual-inertia rotation combines central-shaft and orbital motion for smoother texture.

- Central agitator ensures uniform mixing, minimizes friction, and boosts performance.

Intelligent Control – Flexible Process Management

- Touch-screen interface with control over four key parameters:

time, conching temperature, emulsification intensity, and oxidation airflow. - Ability to store and recall settings for different chocolate recipes.

3. INVESTMENT BENEFITS

- Guarantees consistent quality across batches.

- Enhances natural cocoa flavor for premium artisanal chocolate.

- Reduces manual handling and processing time through automation.

- Robust stainless-steel design for easy cleaning and continuous use.

- Optimized productivity for professional Bean-to-Bar facilities.

4. TECHNICAL SPECIFICATIONS

Specification | Value |

Electrical specification | 400V / 3 ph / 50 Hz |

Power required | 4 kW – 16 A – 5 poles |

Tank capacity | 200 kg |

Dimensions LxWxH | 620 × 710 × 1460 mm |

Origin | Italy |

SELMI CONCA 400 - Conching machine

Voltage

400 V,3 phase ,50 Hz

Power consumption

4 Kw–16A–5 poles

Dimensions

(LxWxH)

950x960x1370 mm

Tank capacity

200 Kg

DETAILED PRODUCT INFORMATION

1. OVERVIEW

Brand: Selmi – Italy

Application Segment: Large-scale Bean-to-Bar chocolate production

Equipment Introduction:

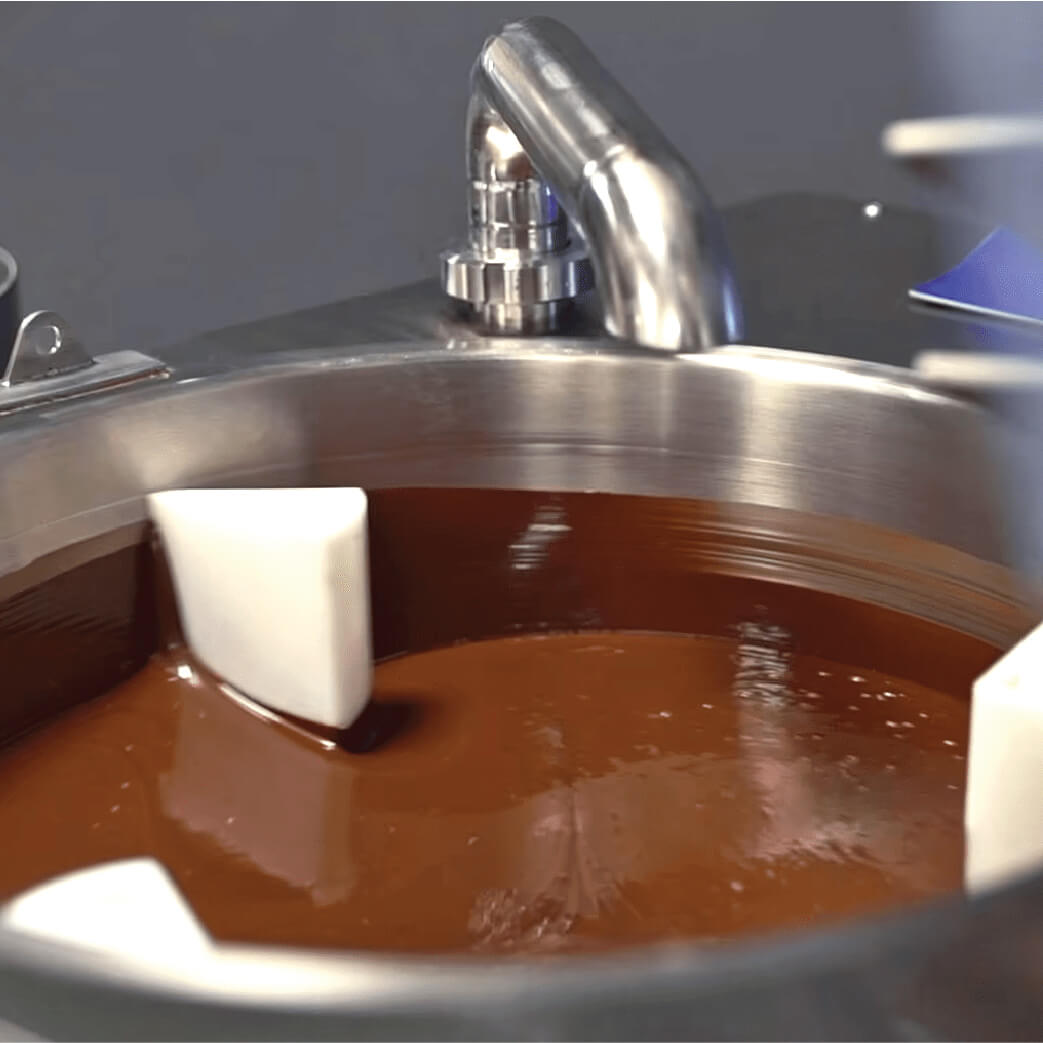

- The Selmi Conca 400 is a high-capacity professional conching system developed for large Bean-to-Bar producers demanding exceptional texture, flavor, and product consistency.

- This model removes volatile acids and moisture while developing natural cocoa aroma and smoothness for premium-grade chocolate.

- With a working capacity of up to 350 kg, the Conca 400 delivers outstanding efficiency for industrial chocolate facilities, optimizing both productivity and quality in every batch.

2. KEY FEATURES

Flavor Development – Structural Perfection

- Conching process of 8–12 hours eliminates acidity and moisture, achieving balanced, deep flavor.

- Preserves the natural aroma and complexity of cocoa for refined, premium chocolate.

Dual-Inertia Mixing System – Exceptional Performance

- Combined shaft and orbital rotation delivers powerful, even mixing.

- Central agitator continuously stirs within a heated tank, ensuring a fine and uniform texture.

Touch-Screen Control – Flexible Process Management

- Interface allows precise adjustment and monitoring of four parameters:

time, conching temperature, emulsification intensity, and oxidation airflow. - Recipes can be stored and repeated for different chocolate formulations.

3. INVESTMENT BENEFITS

- Enhances chocolate flavor and quality to international standards.

- High-capacity production suited for industrial-scale Bean-to-Bar facilities.

- Reduces labor time while maintaining batch consistency.

- Durable stainless-steel construction for continuous, low-maintenance operation.

- The ideal solution for producers expanding Bean-to-Bar operations to higher output levels.

4. INVESTMENT BENEFITS

Specification | Value |

Electrical specification | 400V / 3 ph / 50 Hz |

Power required | 5 kW – 16 A – 5 poles |

Tank capacity | 350 kg |

Dimensions LxWxH | 950 × 960 × 1370 mm |

Origin | Italy |