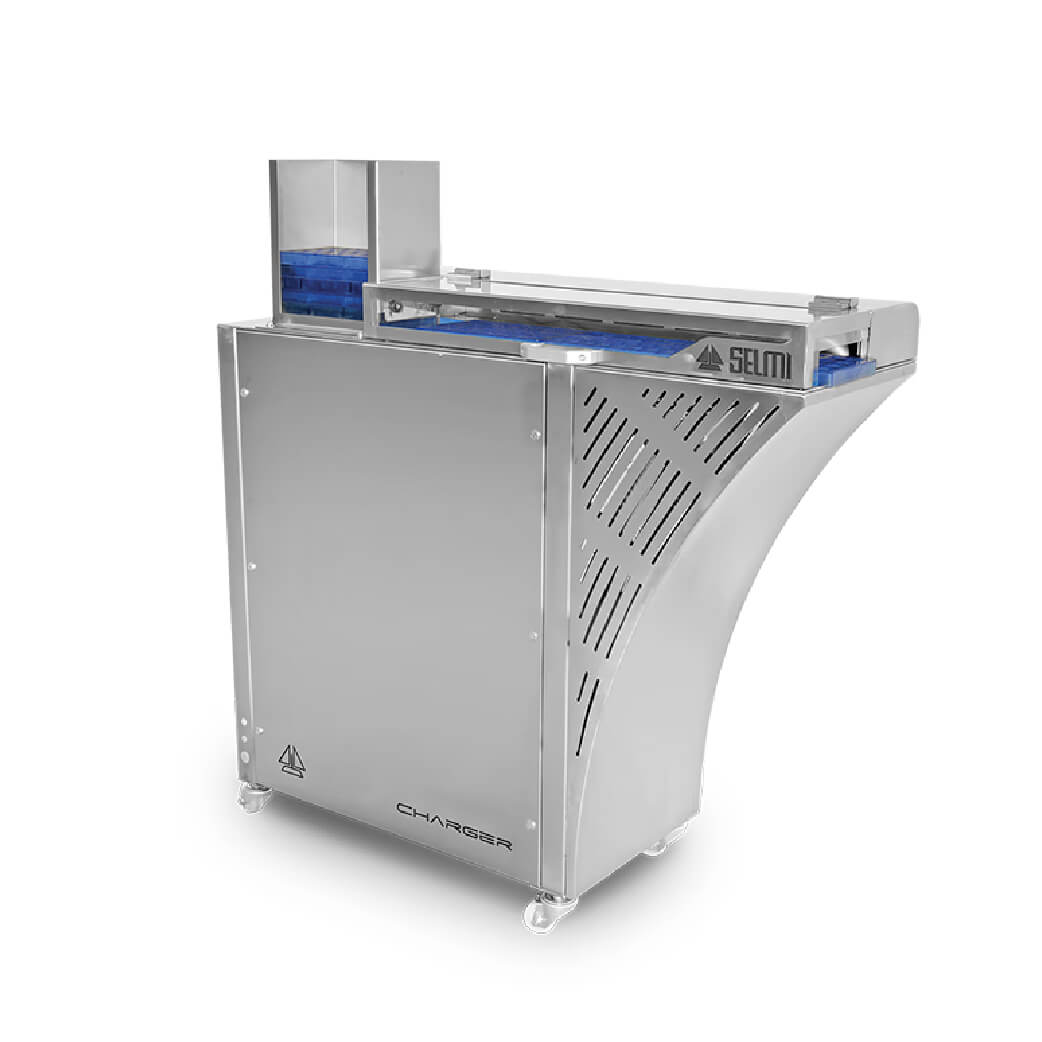

SELMI CHARGER 175/275 - AUTOMATIC MOULD HEATER & LOADER

Voltage

220 V/1 Phase/50 Hz

Power

1.5 Kw

Hourly mold loading

450-1000 molds

Weight

130 Kg

Mold size

175/275 mm

Dimensions

(LxWxH)

1500x1000x1400 mm

DETAILED PRODUCT INFORMATION

1. OVERVIEW

Brand: Selmi – Italy

Application Segment: Automatic OneShot lines (TUTTUNO 4 / 9).

Equipment Introduction:

- Charger 175/275 automatically feeds and warms moulds, synchronized with Selmi TUTTUNO.

- Using resistance heaters and forced-air convection, it keeps moulds at a uniform, ideal temperature prior to depositing—improving shell adhesion and gloss.

- Connects directly to VIBRA, SPIDER, or TUNNEL 400/600 to form a continuous OneShot line..

2. KEY FEATURES

- 2-in-1: Automatic feeding + electric pre-heating to prevent thermal shock.

- Accurate temperature control: Electronic controller with recipe-based setpoints.

- Optical & mechanical positioning: Precise mould alignment.

- Synchronized with TUTTUNO 4 & 9: Auto feed at line speed.

- AISI 304 build: Robust, easy to sanitize, CE-compliant.

3. INVESTMENT BENEFITS

- Brighter, glossier shells without fat bloom thanks to thermally stable moulds.

- Up to +40% line efficiency via uninterrupted mould supply.

- Reduced staffing and misfeeds.

- 24/7 operation-ready for premium praline and bar production..

4. TECHNICAL SPECIFICATIONS

|

Specification |

Value |

|

Electrical supply |

220 V / 1 ph / 50 Hz |

|

Power Required |

≈ 1.5 kW – 16 A – 3 poles |

|

Dimensions (L × W × H) |

1 500 × 1 000 × 1 400 mm |

|

Machine weight |

≈ 130 kg |

|

Feed speed |

450–1,000 moulds/hour (per TUTTUNO model) |

|

Mould formats |

175 mm / 275 mm (select at order) |

|

Construction |

AISI 304 stainless steel |

|

Origin |

Italy ( Italy ) |