CHocolate

Selmi is the world’s leading brand of equipment for the Chocolate industry. Owning Selmi machines not only helps to ensure the best and most efficient production process, but also a guarantee of product quality, brand-class.

Vietnam is known as one of the few countries with high quality cocoa beans and has the “best chocolate lines in the world” – New York Times. Recently, the trend of investing in cocoa cultivation & high-quality chocolate production in Vietnam has been strongly developed, creating new prospects.

As the official representative of Selmi in Indochina, TIM CORP wishes to bring the best machines, along with the most effective technical solutions to help chocolate manufacturers in Vietnam create chocolate products. Made In Vietnam is proud of.

CHOCOLATE EQUIPMENT

SELMI – Chocolate Processing Machine

In 1965 Renato Selmi began processing hazelnut flour, then moved to Chocolate brewing and packaging machines.

Growth began to take off in 1987, when Paolo Selmi entered the business with his father. Since that time, the combination of technology, knowledge of raw materials and a relentless drive for efficiency and perfection has made the company a national and international leader. in the field of manufacturing machinery for manual chocolate processing and the field of roasting coffee and nuts.

Selmi is a brand that cannot be ignored when it comes to machines and accessories for chocolate processing in all forms: pralines, bars, truffles, chocolate snacks, chocolate bean to bar, spreadable creams.

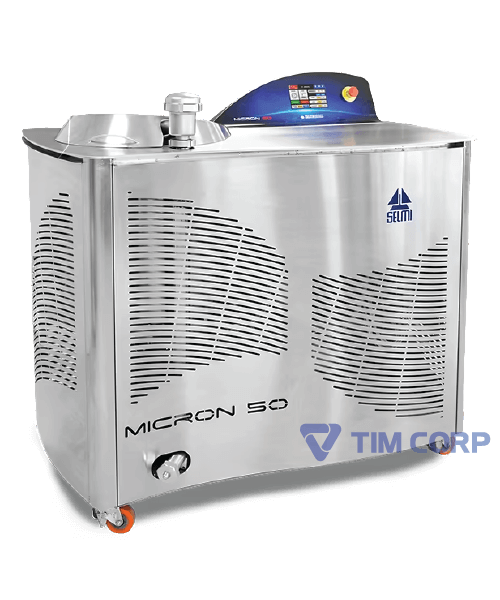

TEMPERING LINE

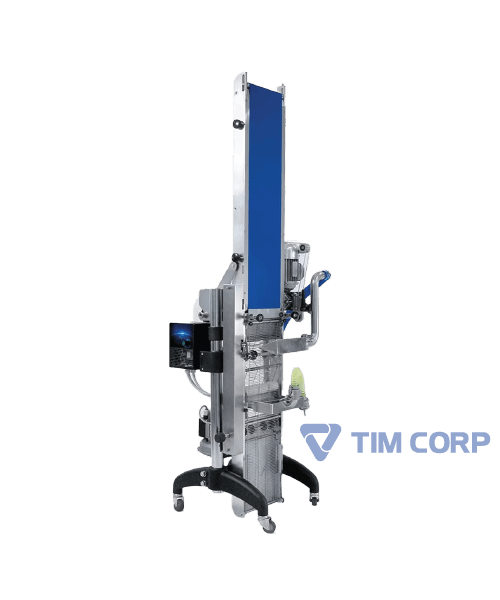

COATING MACHINES

REFINING MACHINES

ROASTER MACHINES

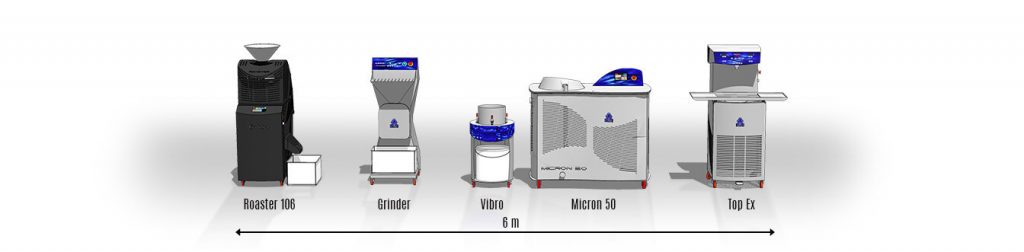

Bean to BAR

Selmi’s Chocolate production line is a hand-crafted but unique production line. Providing equipment from roasting beans to creating pure chocolate, the production line is easy to operate and easy for users to control.

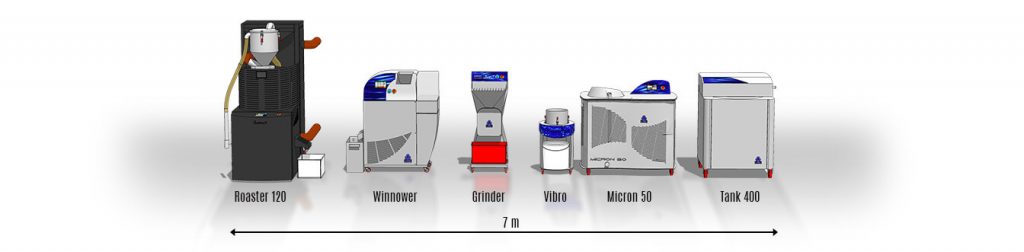

Configuration: DARK CHOCOLATE

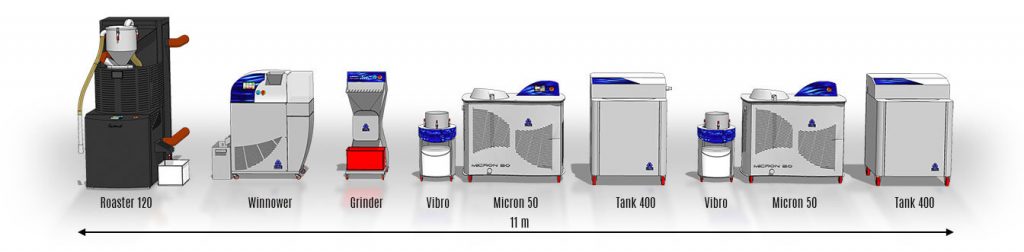

Configuration: DARK CHOCOLATE + MILK CHOCOLATE

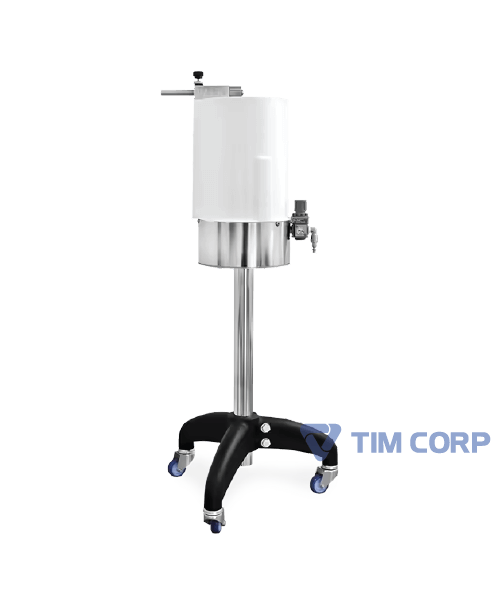

NUTS PROCESSING

With friendly but unique craft technology, Selmi has provided a full range of equipment necessary for the production of products made from raw materials of nuts. Supply equipment from roasting the seeds to creating pure refined pastes. By equipping all necessary machines to help users easily control the production and easily diversify products in their own way, improving the value of raw materials.